Energy Storage System (ESS) Liquid Cooling Chiller

4 days ago · Liquid cooling refers to the use of liquid cooling media such as water, mineral oil, ethylene glycol, etc. for cooling. Compared to air cooling, it provides better heat exchange

Liquid cooling meets electrochemical storage | C&I Energy Storage

Now, imagine that same heat challenge for large-scale energy storage systems. As renewable energy adoption surges, managing the thermal stress of batteries has become a mission

Engineering Design of Liquid Cooling Systems in

Jul 3, 2025 · A well-integrated Liquid Cooled Energy Storage Cabinet doesn''t just run cooler—it runs smarter and lasts longer. In practical applications like

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integra

Energy Storage System Cooling

May 5, 2025 · Background Energy storage systems (ESS) have the power to impart flexibility to the electric grid and offer a back-up power source. Energy storage systems are vital when

Modeling and analysis of liquid-cooling thermal

Sep 1, 2023 · A self-developed thermal safety management system (TSMS), which can evaluate the cooling demand and safety state of batteries in real-time, is equipped with the energy

Industrial and commercial energy storage system liquid cooling

Jun 14, 2024 · 1. Industrial and commercial energy storage system liquid cooling design For the high-rate charging and discharging process of large-scale battery packs, the cooling capacity

125KW/233KWh Liquid-Cooling Energy Storage

Dec 30, 2024 · In order to ensure the safety of energy storage power stations, the selection and design of energy storage system equipment should follow the principles of "prevention first,

Numerical study on heat dissipation and structure

May 1, 2024 · Satyanarayana et al. (Satyanarayana et al., 2023) examined the cooling effects of natural air cooling, forced air cooling and immersion liquid cooling on battery modules, and the

Containerized Liquid Cooling ESS VE-1376L

Sep 8, 2023 · Vericom energy storage cabinet adopts All-in-one design, integrated container, refrigeration system, battery module, PCS, fire protection, environmental monitoring

125KW/261KWh Liquid-Cooling Energy Storage All

Apr 28, 2024 · 125KW/261KWh Liquid-Cooling Energy Storage All- in-One Machine Equipment Technical Specification Anhui Lvwo Energy Technology Co., Ltd April 28, 2024

Liquid-Cooled Electrochemical Energy Storage: The Future of

Feb 21, 2021 · Final Thought: Are We at Peak Cooling? With companies like Northvolt testing cryogenic (-40°C) cooling for ultra-dense storage, the answer''s clear: we''re just getting started.

Energy storage cooling system

Dec 8, 2024 · Compared with air-cooled systems, liquid cooling systems for electrochemical storage power plants have the following advantages: small footprint, high operating efficiency,

液冷散热技术在电化学储能系统中的研究进展

Apr 1, 2024 · The findings indicate that liquid cooling systems offer significant advantages for large-capacity lithium-ion battery energy storage systems. Key design considerations for liquid

Liquid Cooling Energy Storage: The Next Frontier in Energy Storage

Apr 5, 2025 · Liquid-cooled energy storage is becoming the new standard for large-scale deployment, combining precision temperature control with robust safety. As costs continue to

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · Representative energy storage methods include mechanical energy storage, electrical energy storage, and electrochemical energy storage. The electrochemical energy

Multi-objective topology optimization design of liquid-based cooling

Feb 1, 2025 · In this work, the liquid-based BTMS for energy storage battery pack is simulated and evaluated by coupling electrochemical, fluid flow, and heat transfer interfaces with the

C&I liquid-cooled outdoor energy storage cabinet

C&I liquid-cooled outdoor energy storage cabinet offered by China manufacturer RAJA. Buy C&I liquid-cooled outdoor energy storage cabinet directly with low price and high quality.

Electrochemical Energy Storage Heat Dissipation Methods: Air Cooling

Apr 10, 2024 · Temperature management is crucial in energy storage systems, especially for electrochemical energy storage systems like lithium-ion batteries. Proper temperature

Electrochemical Energy Storage Electricity Price: Trends,

Mar 11, 2025 · a technology that can store sunshine for nighttime use and bank wind energy for calm days. Welcome to the wild world of electrochemical energy storage, where electricity

5 FAQs about [Liquid cooling medium for electrochemical energy storage cabinet]

Which energy storage system is better – liquid cooled or air cooled?

3.Energy storage: Compared with traditional air-cooled energy storage systems, liquid-cooled systems are more suitable for large-scale and long-term energy storage. 4.

What is liquid cooling technology?

At present, the proportion of liquid cooling technology in new large-scale storage projects on the power generation side/grid side is rapidly increasing. Liquid cooling refers to the use of liquid cooling media such as water, mineral oil, ethylene glycol, etc. for cooling. Compared to air cooling, it provides better heat exchange capacity.

What is the technology roadmap for thermal management of energy storage?

At present, the mainstream Technology roadmap of thermal management of energy storage is air cooling and liquid cooling. At present, the proportion of liquid cooling technology in new large-scale storage projects on the power generation side/grid side is rapidly increasing.

What type of cooling unit does lneya use?

The cooling unit of our LNEYA is air-cooled, water-cooled and liquid-cooled. However, with the development and trend of the industry, liquid cooling will become the mainstream.

Why is thermal management important in the electrochemical energy storage industry?

Due to the thermal characteristics of batteries, thermal management has become a key link in the electrochemical energy storage industry chain.

Learn More

- Liquid Cooling Energy Storage Cabinet Commercial Use

- How to charge the battery cabinet liquid cooling energy storage solar panels

- Liquid cooling energy storage cabinet composition structure

- Guinea-Bissau Liquid Cooling Energy Storage Cabinet Production

- Liquid Cooling Energy Storage Battery Cabinet

- Power supply for energy storage cabinet liquid cooling processing site

- Energy storage cabinet liquid cooling production line

- Dili 210 degree liquid cooling energy storage cabinet foreign trade

- Energy storage liquid cooling battery cabinet design

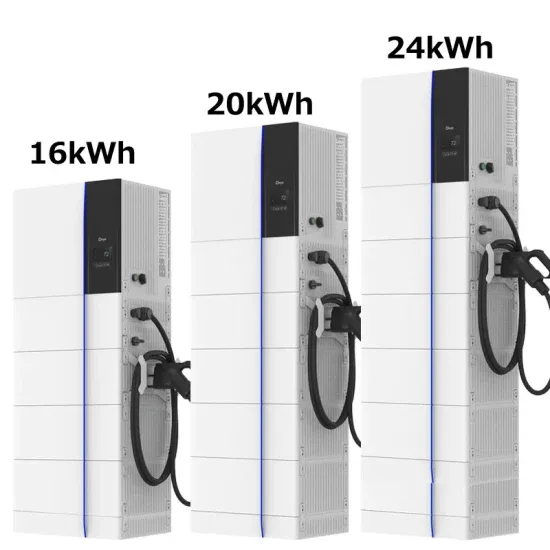

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.