Peak Sun Hours Calculator (by address, city, or

Nov 29, 2024 · Or you can do a reverse calculation to estimate how much energy can the solar power system generate in your location. One (1) kW of the solar

Solar PV energy: From material to use, and the most

Nov 1, 2022 · A PV system generate electricity by converting solar energy directly into electricity using PV cells (solar panels/modules), which are the system''s most important components

A review of hybrid renewable energy systems: Solar and

Dec 1, 2023 · The review comprehensively examines hybrid renewable energy systems that combine solar and wind energy technologies, focusing on their current challenges,

Introduction to Photovoltaic Solar Energy

Jan 1, 2025 · Photovoltaic (PV) solar cells transform solar irradiance into electricity. Solar cells, primarily made of crystalline silicon, are assembled in arrays to produce PV modules. PV

PVWatts Calculator

Mar 13, 2025 · NREL''s PVWatts ® Calculator Estimates the energy production of grid-connected photovoltaic (PV) energy systems throughout the world. It allows homeowners, small building

Photovoltaics and electricity

May 24, 2024 · A PV cell is made of semiconductor material. When photons strike a PV cell, they will reflect off the cell, pass through the cell, or be absorbed by the semiconductor material.

Solar irradiance estimation and optimum power region localization in PV

Aug 1, 2023 · The ANN receives as inputs, the estimate of solar irradiance from the three PV modules under PSC and outputs a minimum and maximum voltage level according to Table 2.

How to Calculate the Surface Area Required by

May 27, 2013 · Lets assume that you want to install 10 solar panels rated at 100 Watts each and having a conversion efficiency of 18%. The total power output

Solar Irradiance Calculation Guide

Jun 20, 2025 · When designing a solar plant, irradiance is typically the first parameter evaluated. Platforms like ARKA 360''s Design Studio automate this process, generating accurate

Solar Energy, Solar FAQ

Feb 16, 2023 · Solar irradiance is often integrated over a given time period in order to report the radiant energy emitted into the surrounding environment (joule per square metre, J/ m2),

Photovoltaic Effect: An Introduction to Solar Cells

Feb 10, 2006 · In a photovoltaic device, there is a built-in asymmetry (due to doping) which pulls the excited electrons away before they can relax, and feeds them to an external circuit. The

Maximizing Solar Irradiance for Optimal Solar

May 6, 2025 · When it comes to solar energy, one term you''ll hear often is "solar irradiance." But what exactly does it mean, and why is it so important for solar

Minimum power generation conditions for solar panels

What is solar panel shading loss? Solar photovoltaic (PV) systems generate electricity via the photovoltaic effect -- whenever sunlight knocks electrons loose in the silicon materials that

6 FAQs about [The minimum irradiance at which photovoltaic panels can generate electricity at full load]

What irradiance should a solar panel be placed in?

Understanding solar irradiance is pivotal when determining the best placement for photovoltaic (PV) panels. The amount of solar energy a panel can generate is directly proportional to the solar irradiance it receives. Therefore, panels are best placed in areas with high solar irradiance.

How does irradiance affect the power of a PV module?

Similarly, we can observe the voltage and power relationship of a PV module at different irradiance levels. We can see that as irradiance increases, the module is able to generate more power, represented by higher peaks on the curves in Figure 2.8.

How does solar irradiance affect the performance of a solar system?

The performance of a PV system is directly tied to how much sunlight it receives. This is measured by solar irradiance —the amount of solar power received per unit area. When designing a solar plant, irradiance is typically the first parameter evaluated.

What is solar irradiance?

In solar terms, irradiance represents the intensity of sunlight falling on the solar panel. That is, irradiance is an instantaneous measurement of solar power over some area at some point in time with maximum irradiance present at noon on a clear day.

How accurate is solar irradiance at ground level?

However, actual irradiance at ground level varies depending on location, time of day, season, terrain, and weather. Understanding the three main components of irradiance is key to accurate solar design: The total solar power received per unit area at the Earth’s outer atmosphere, measured across all wavelengths.

How is solar irradiance measured?

This is measured by solar irradiance —the amount of solar power received per unit area. When designing a solar plant, irradiance is typically the first parameter evaluated. Platforms like ARKA 360’s Design Studio automate this process, generating accurate irradiance maps remotely—saving time and reducing errors.

Learn More

- Minimum requirements for photovoltaic panels to generate electricity

- Small photovoltaic panels connected in parallel to generate electricity

- Does Kuwait s photovoltaic panels generate a lot of electricity

- Can photovoltaic panels and thermal insulation glass generate electricity

- Will photovoltaic panels generate electricity

- The hotter the weather the more electricity photovoltaic panels can generate

- Can photovoltaic panels generate electricity

- Can photovoltaic panels generate electricity by shading the sun

- Tile-like panels generate more electricity than ordinary photovoltaic panels

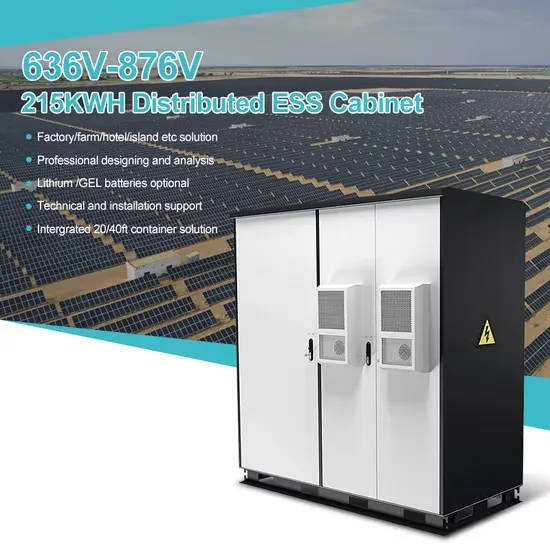

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.