Photovoltaic inverters: What are they and how

Jul 8, 2024 · Photovoltaic inverters are devices that transform the direct current (DC) generated by solar panels into alternating current (AC). That is, solar

How does a solar inverter work? (Functions, types, and

Jun 2, 2025 · Can you monitor photovoltaic inverter performance? Yes, most PV inverters include built-in monitoring systems that let you track system performance in real time. You can:

An Introduction to Inverters for Photovoltaic (PV)

Jan 18, 2012 · An inverter is an essential part of any grid-connected PV plant, which is an environmentally power generation system that uses the photovoltaic effect to convert sunlight

What is a Photovoltaic Module? A Comprehensive Definition

Jul 16, 2025 · Understanding the Design and Efficiency of Photovoltaic Modules Understanding the photovoltaic module definition is crucial for homeowners, as the design of photovoltaic

Chapter Number 3.0 Solar PV modules Explained in detail

Mar 29, 2023 · A solar PV module is a collection of solar cells, mainly connected in series. These combinations of Solar Cell provide higher power than a single solar cell. The PV modules are

6 FAQs about [What is a photovoltaic inverter module]

What does a solar inverter do?

Because of its main functions, the inverter is known as the “heart and brain” of the PV system. converting direct current into alternating current for use in the home. monitoring the current and voltage values of the solar modules to ensure they’re always delivering the best possible output.

What is a PV inverter and how does it work?

One critical task of the inverter is to make sure that the PV modules are always working at their optimum power levels: Depending on temperature and irradiation intensity, there is always a precise combination of electrical current and voltage that allows a PV module to achieve its maximum power, which is also called its maximum power point or MPP.

What power category should a photovoltaic inverter be used for?

The appropriate power category for the inverter will depend on the size of the photovoltaic system, so the best thing to do is to get advice from a professional installer in your area. Because of its main functions, the inverter is known as the “heart and brain” of the PV system.

What types of inverters are used in photovoltaic applications?

This article introduces the architecture and types of inverters used in photovoltaic applications. Inverters used in photovoltaic applications are historically divided into two main categories: Standalone inverters are for the applications where the PV plant is not connected to the main energy distribution network.

How to pair a solar inverter with a PV plant?

In order to couple a solar inverter with a PV plant, it’s important to check that a few parameters match among them. Once the photovoltaic string is designed, it’s possible to calculate the maximum open-circuit voltage (Voc,MAX) on the DC side (according to the IEC standard).

What is the I-V curve of a solar PV module?

As a standard rule, this curve is available in each PV module’s datasheet and is calculated according to the Standard Test Condition, STC: (1000 W/m2, 25 °C, IAM 1.5). To better understand IAM, read How Radiation and Energy Distribution Work in Solar PV. Figure 3 - Example of I-V curve of a PV module. Image courtesy of PVEducation.

Learn More

- What are the types of photovoltaic module batteries

- What is the photovoltaic inverter current

- What battery should be connected to the photovoltaic panel inverter

- What is a photovoltaic inverter with energy storage

- Advantages and disadvantages of photovoltaic integrated inverter

- Photovoltaic inverter trading

- Namibia inverter off-grid module multiple installations

- Photovoltaic inverter photovoltaic combiner box

- Photovoltaic grid-connected inverter overcapacity configuration

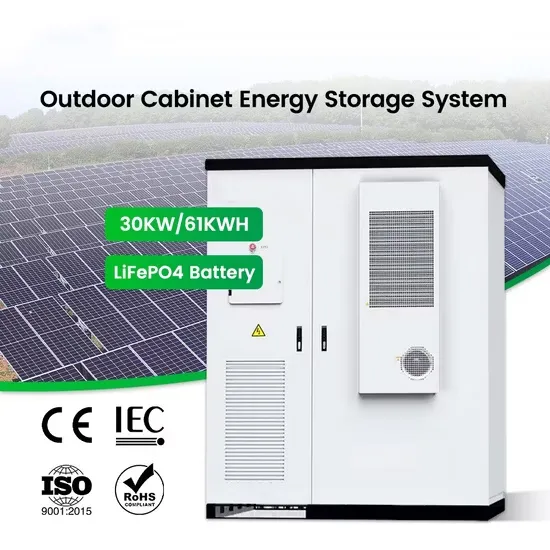

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.