Top Energy Storage Battery Cabinets in 2025: Which One

Dec 29, 2020 · Ever wondered why tech giants and solar farms are suddenly obsessed with metal cabinets? Meet the energy storage battery cabinet—the unsung hero of modern power

Energy Storage Tank Cars: The Mobile Powerhouses Revolutionizing Energy

Jan 8, 2021 · Enter the energy storage tank car – think of them as "battery banks on wheels" that bring emergency power to disaster zones or store excess solar energy like liquid sunshine.

Energy Storage Vehicle Composition: Breaking Down the

Dec 2, 2024 · Ever wondered how your EV manages to store energy so efficiently? Let''s peel back the layers of energy storage vehicle composition —the unsung hero behind every electric

Spring Energy Storage in Cars: The Comeback of Mechanical

Cars equipped with spring energy storage are gaining traction as manufacturers seek alternatives to lithium-ion battery dominance. These mechanical marvels use compressed springs - yes,

Electric Cars: More Than Just Batteries on Wheels | C&I Energy Storage

Apr 13, 2020 · Battery Types: Most EVs use lithium-ion, but solid-state batteries (think: safer, faster-charging) are racing to market. Energy Density: Newer batteries pack 30% more energy

Types Of Energy Storage Systems In Electric Vehicles

Jan 18, 2024 · Electric car batteries serve as dynamic storage solutions capable of storing excess energy generated during peak times and releasing it when

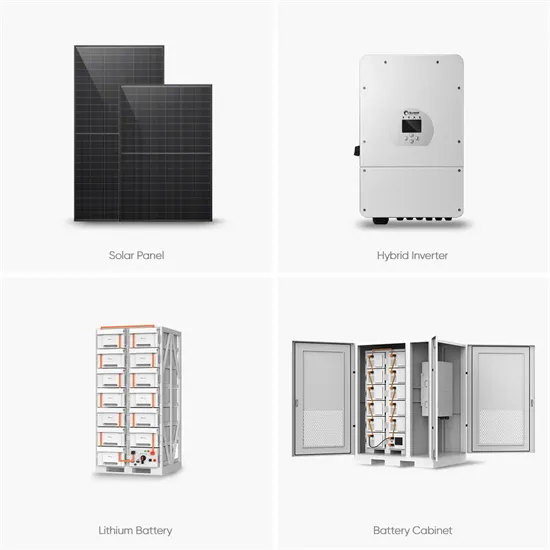

How to design an energy storage cabinet: integration and

Jan 3, 2025 · As the core equipment in the energy storage system, the energy storage cabinet plays a key role in storing, dispatching and releasing electrical energy. How to design an

Top 10 Electric Vehicles with Next-Gen Energy Storage Batteries

Apr 20, 2023 · Welcome to the solid-state battery era—where cars are ditching liquid electrolytes faster than TikTok trends. With energy density hitting 400Wh/kg (that''s 2x your current lithium

Used Car Batteries for Energy Storage: A Sustainable Power

The Science Behind Second-Life Batteries Car batteries—especially lithium-ion and lead-acid types—retain up to 70% capacity after their automotive lifespan ends [9]. Instead of discarding

Potential of electric vehicle batteries second use in energy storage

Aug 15, 2022 · Battery second use, which extracts additional values from retired electric vehicle batteries through repurposing them in energy storage systems, is pr

What are the energy storage battery cars? | NenPower

Aug 28, 2024 · 1. Energy storage battery cars utilize rechargeable batteries to store energy, enabling electric propulsion in vehicles. 2. These vehicles operate silently, producing zero

Energy Storage Systems: Powering The Future Of Cars

May 29, 2025 · Lithium-ion batteries are currently the dominant battery system in electric vehicles due to their high energy density and long life cycle. They also have a high power-to-weight

Energy storage technology and its impact in electric vehicle:

Jan 1, 2025 · Use of auxiliary source of storage such as UC, flywheel, fuelcell, and hybrid. The desirable characteristics of an energy storage system (ESS) to fulfill the energy requirement in

What does the energy storage cabinet include? | NenPower

Sep 22, 2024 · The energy storage cabinet encompasses a sophisticated array of components and technologies designed to facilitate the effective storage and management of electricity

Battery Storage Cabinets: The Backbone of Safe

Apr 11, 2025 · Explore the essential role of battery storage cabinets in modern energy systems, highlighting their design, safety features, and applications

PCS-8812PB Liquid cooled energy storage cabinet

NR Electric Co. LtdPCS-8812 liquid cooled energy storage cabinet adopts liquid cooling technology with high system protection level to conduct fine temperature control for outdoor

What kind of battery is used in the energy storage cabinet

Apr 6, 2024 · Lastly, Nickel-cadmium batteries are durable in adverse conditions, although their use is less common due to environmental concerns related to cadmium. A thorough

How many battery cars can the energy storage box hold?

Jun 24, 2024 · To determine how many battery cars can be supported by an energy storage box, one must consider several factors. 1. Energy capacity of battery cars, 2. Energy capacity of the

6 FAQs about [Which cars can use the energy storage cabinet battery]

Which energy storage sources are used in electric vehicles?

Electric vehicles (EVs) require high-performance ESSs that are reliable with high specific energy to provide long driving range . The main energy storage sources that are implemented in EVs include electrochemical, chemical, electrical, mechanical, and hybrid ESSs, either singly or in conjunction with one another.

Which energy storage systems are suitable for electric mobility?

A number of scholarly articles of superior quality have been published recently, addressing various energy storage systems for electric mobility including lithium-ion battery, FC, flywheel, lithium-sulfur battery, compressed air storage, hybridization of battery with SCs and FC , , , , , , , .

What kind of batteries do electric vehicles use?

Electric vehicles employ a variety of lithium-based batteries, which have been around since 1991.

Are lithium-ion batteries suitable for EV applications?

Radar based specified techniques is employed to analyse the various performance parameters of battery technology in electric mobility. A comparison and evaluation of different energy storage technologies indicates that lithium-ion batteries are preferred for EV applications mainly due to energy balance and energy efficiency.

Are Lib batteries a good choice for electric vehicles?

It is also revealed from this analysis that LIBs have low environmental impact as compared to other batteries technology. Metal-air battery technology has a comparable lifespan, but it is lacking in terms of production rate and other operating parameters as compared to LIB technology for electric vehicles.

What type of batteries are used in energy storage devices?

For energy storage devices' EMS, FC batteries are used. They are crucial in the interplay between renewable energy sources and power grids and microgrids , . HES with high specific power and specific energy include FC and VRLA, FC and NiMH, and FC and Li-ion . 3.6.4. Fuelcell-capacitor HES

Learn More

- Which battery energy storage should I choose for home use

- Which solar energy storage cabinet is cheap and easy to use

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

- Kuwait battery energy storage cabinet manufacturer

- Energy storage cabinet battery single selling price

- How to use the photovoltaic energy storage cabinet site

- Chemical protection lithium battery energy storage cabinet base station

- Energy storage battery use in Guatemala

- What kind of battery does Cameroon Energy Bee use for energy storage

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.