CRITICAL SAFETY PROTOCOL FOR LITHIUM BATTERY

Mar 20, 2025 · CRITICAL SAFETY PROTOCOL FOR LITHIUM BATTERY INSTALLATION AND MAINTENANCE This document emphasize the crucial importance of adhering to stringent

Kweli Energy 8kVA-20kWh Lithium Battery-Inverter Backup

Inverter-Battery Backup Safety Kit – a complete set of safety and protection devices that safeguard your system and appliances against overloads, short circuits, and surges.

Kweli Energy 6kVA-20kWh Lithium Battery-Inverter Backup

Inverter-Battery Backup Safety Kit – a complete set of safety and protection devices that safeguard your system and appliances against overloads, short circuits, and surges.

Kweli Energy 6kVA-15kWh Lithium Battery-Inverter Backup

Inverter-Battery Backup Safety Kit – A complete set of safety and protection devices that safeguard your system and appliances against overloads, short circuits, and surges.

1 Product and Company Identification USA, EU

Mar 22, 2021 · Further Information Battery-System: Lithium-Ion (Li-ion) Voltage: 3.2V Anode (negative electrode): based on intercalation graphite Cathode (positive electrode): based on

Traditional Inverters vs. Lithium-Ion Inverters: A Comparison

Jun 13, 2025 · Explore the future of power backup with the next-gen lithium-ion battery inverter—a solution that goes beyond being just an inverter. Here is a quick comparison between

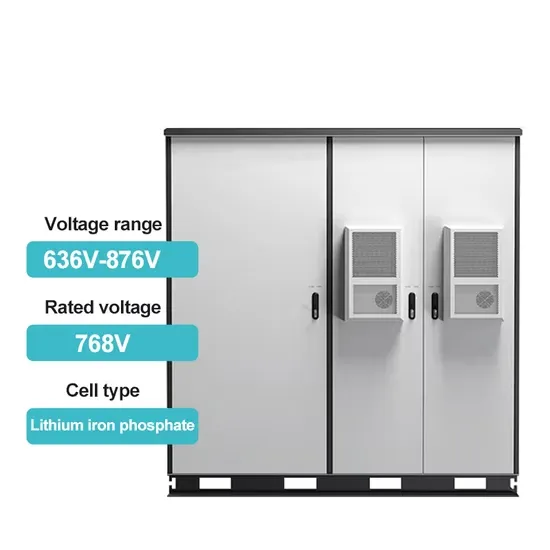

How to design an energy storage cabinet: integration and

Jan 3, 2025 · Efficient heat dissipation design: Lithium batteries and inverters will generate a certain amount of heat during operation, so the energy storage cabinet requires an effective

A Guide to Lithium-Ion Battery Safety

Jun 11, 2019 · Safety characteristics vary by Li-ion electrochemistry Overcharged (delithiated) positive can become unstable Passivation layer (SEI) can break down above 100°C

Solar power, inverters & lithium batteries – Safety measures

Apr 11, 2025 · Furthermore, fire-damaged batteries or inverters may expose live terminals, increasing the risk of electrical shock or electrocution. Some lithium battery chemistries,

Buy Lithium Ion Inverter Battery At Best Price In

5 days ago · Buy UTL Lithium Ion inverter batteries at unbeatable price in India. It''s loaded with amazing features like fast charging, Zero maintenance, no

Lithium Battery for Inverter: The Guide to Power Your Home

When choosing a lithium-ion battery for your inverter, consider factors such as capacity, safety features, and compatibility with your inverter system. With the right battery, you can future

Kweli Energy 6kVA-10kWh Lithium Battery-Inverter Backup

Inverter-Battery Backup Safety Kit – A complete set of safety and protection devices that safeguard your system and appliances against overloads, short circuits, and surges.

How to Choose the Right Inverter for Lithium Batteries?

Apr 11, 2025 · Answer: To choose the right inverter for lithium batteries, match the inverter''s voltage and capacity to your battery''s specifications, prioritize pure sine wave inverters for

A Brighter Future: Exploring Lithium Batteries For

Aug 4, 2023 · Overcoming Challenges and Future Trends As you explore the potential of lithium batteries for inverter systems, it''s important to understand

Do I Need a Special Inverter for a Lithium Battery?

Oct 25, 2024 · High-efficiency inverters minimize energy loss during conversion, which is particularly important for maximizing the performance of lithium batteries. Choose inverters

Lithium Battery Safety: Understanding the Risks

Mar 28, 2024 · When a lithium battery fails, the most dangerous result is a fire, known as a thermal runaway: Intense heat: Lithium battery fires can burn at

Kweli Energy 8kVA-15kWh Lithium Battery-Inverter Backup

Inverter-Battery Backup Safety Kit – A complete set of safety and protection devices that safeguard your system and appliances against overloads, short circuits, and surges.

Best Inverter For Lithium Ion Battery (2025

Jun 3, 2025 · Special inverters for lithium batteries will optimize the battery''s performance and provide the necessary safety features to protect the battery

Are Lithium Batteries Safe to Use? Myths vs. Facts

Dec 20, 2024 · A safer and more reliable alternative in the lithium family. LiFePO4 (lithium iron phosphate) batteries are designed for enhanced safety, making

Are Power Inverters Bad for Your Battery? Risks, Effects, and Safety

Mar 29, 2025 · Power inverters change battery power into AC power. If the inverter demands more power than the battery can provide, it causes excessive discharge. This can shorten the

6 FAQs about [Lithium battery inverter safety]

Are lithium ion batteries safe?

When selecting battery technologies for energy storage, it is important to understand the safety differences between the available options. Standard lithium-ion batteries—often composed of lithium cobalt oxide (LiCoO₂)—are widely used due to their high energy density but are more susceptible to overheating and thermal runaway.

What are the risks of a battery inverter?

The accumulated thermal pressure or gases within battery cells can also cause violent explosions, which pose significant risks to people and property. Furthermore, fire-damaged batteries or inverters may expose live terminals, increasing the risk of electrical shock or electrocution.

How to maintain a battery inverter?

Ensure to work in an area with enough airflow that minimizes the chances of the surrounding temperature or any excess gases coming into contact the inverter connected with the battery which could damage or interfere with their performance.

Are lithium batteries flammable?

Some lithium battery chemistries, especially metallic lithium, can react with water, producing flammable hydrogen gas and heightening the risk of fire. Finally, fire-damaged batteries can leak electrolyte fluids, which are corrosive and environmentally harmful.

Why do you need a battery connection for an inverter?

The DC comes from the batteries which are used to power the inverter, and this inverter transforms the power into AC usable by bulbs, fans, and other small electrical devices. You must go through battery connection for inverter while considering the risks of electrical shocks, damage to devices, so that potential fire risks are avoided.

What should I do if my inverter is not working?

Always put on safety gear as the failure to wear insulated gloves and safety glasses may cause exposure to the danger of unintentional electric exposure while connecting the inverter with the battery. Ensure that all devices hooked to the inverter are disconnected and disabled to avoid damaging the battery connection for inverter.

Learn More

- Zagreb lithium battery energy storage system inverter

- What size inverter is suitable for lithium battery

- Sudan 40kw lithium battery energy storage system inverter

- RV lithium battery charging inverter

- Can a 12v inverter be powered by a 14v lithium battery

- Base station lithium battery energy storage 15kw inverter power supply

- North Africa 4-string lithium battery inverter

- Managua base station lithium battery energy storage 30kw inverter

- Which lithium battery is better with inverter

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.