Understanding Base Transceiver Stations: The Backbone of

Jan 1, 2025 · Simply put, a base transceiver station (BTS) is a vital component of mobile networks, serving as the communication hub that connects your mobile phone to the wider

Can signal base stations and signal towers cause radiation

Jan 9, 2025 · First, let''s clarify an important concept: a signal base station is not the same as a signal tower. A base station is a vital component of the communication network, responsible

Tower Base Station AC Distribution Box

Jul 28, 2025 · The program includes a new base station and the stock of base station transformation two parts, respectively, for the two types of use of the environment, put forward

Cell sites and cell towers in a mobile cellular

Nov 17, 2019 · A picture of a cell tower at a cell site Cell site means the location where a cell tower is installed A cell site is a location or "site" where a mobile

Electric distribution box for 5G signal tower

The invention provides an electric distribution box for a 5G signal tower, belongs to the technical field of electric distribution boxes, and aims to solve problems that when the interior of an

Tower Base Station AC Distribution Box

Jul 28, 2025 · 380VAC / 100A intelligent AC power distribution box, designed for new base stations, set up a field-level power distribution and equipment management platform, the oil

CONFIGURATION & INSTALLATION OF A BASE TRANSCEIVER STATION

Feb 16, 2018 · Base Transceiver Station otherwise regarded as Cell is the smallest unit of the Base Station System structure. It''s the area of radio coverage of a BTS.

Distribution Boxes gesis® RAN by Wieland for Power

Wieland is your experienced and reliable partner for efficient, pluggable and decentralized electrical installation. Among our distribution boxes you will find the smart and practical

Integrated Base Station-Signalwing Corporation

The 5G integrated base station product is an important supplement to the mobile communication network, which extends the coverage of the mobile communication network, improves the

Blog -Communication Signal Tower Types & Design,Mobile Base Station

Jul 22, 2024 · In the context of electrical power transmission lines, lattice towers are commonly used to support the conductors that carry electricity from power plants to distribution

Application Note: Distributed Base Stations

Another variation on the Distributed BTS concept is the capacity transfer system, in which a single BTS with a digital connection to the BSC (Base Station Controller) is connected to additional

6 FAQs about [Signal tower base station distribution box]

How does a distribution box work?

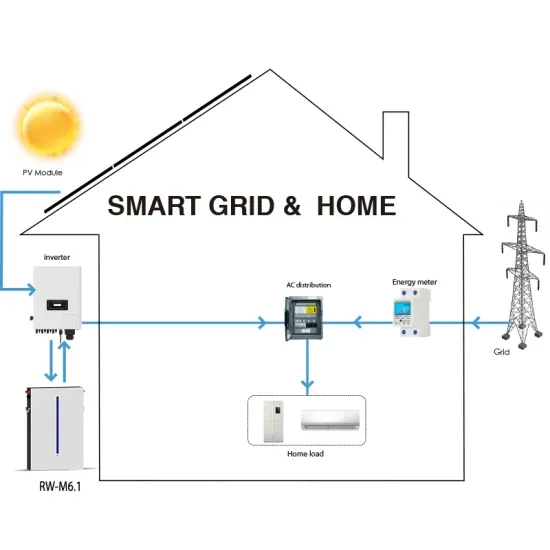

The distribution box operates on a simple yet effective principle of electrical distribution and protection. Here's how it works: Power Input: The distribution box, pivotal in power distribution, serves as the conduit for electrical power sourced from either the utility grid or a generator.

What is a Wieland distribution box?

The Wieland distribution boxes accommodate all required components of the electrical installation as well as building automation on a project-specific basis. The distributor boxes can be viewed as a black box that provides the appropriate interfaces to the field and management levels. What do I need to consider during installation?

Why should you choose a modern distribution box?

Monitoring: Contemporary distribution box are equipped with advanced monitoring capabilities, allowing real-time tracking of power consumption. These intelligent systems can swiftly detect faults and issue alerts, facilitating proactive maintenance or troubleshooting.

Can the Wieland distribution boxes be colored?

Yes, the Wieland distribution boxes can be colored according to your wishes. DISTRIBUTION BOXES - Brochure 0702.1 | 10 MB EXHIBITION DISTRIBUTORS gesis® WIV - Brochure 0705.1 | 4 MB Installation Column – Customized Solutions – Brochure 0404.1 | 7 MB Distribution Box - Smart Installation Brochure 0704.1 | 897 KB

Are GESIS® ran distribution boxes reliable?

Don’t be put on hold. Our experts will call you. The gesis® RAN distribution boxes from Wieland are the reliable solution for your electrical power distribution needs » designed for durability and reliability!

What tests are carried out in a distribution box?

The distribution boxes are subject to a type test, which includes EMC, temperature, IP, the IK test and the corrosion test. In addition, a routine test is carried out, which consists of a visual inspection, a short-circuit and polarity reversal test and a continuity test. A functional test can be performed at the customer's request.

Learn More

- Cape Verde Mobile Company 5G communication signal tower base station

- Communication base station inverter signal tower migration

- How to connect the signal base station battery to the power distribution cabinet

- Ouagadougou 2025 5g base station distribution box

- Base station room distribution box

- Base station distribution box standard

- Communication tower and communication green base station

- Distribution cabinet warehouse container base station

- Distribution cabinet container base station

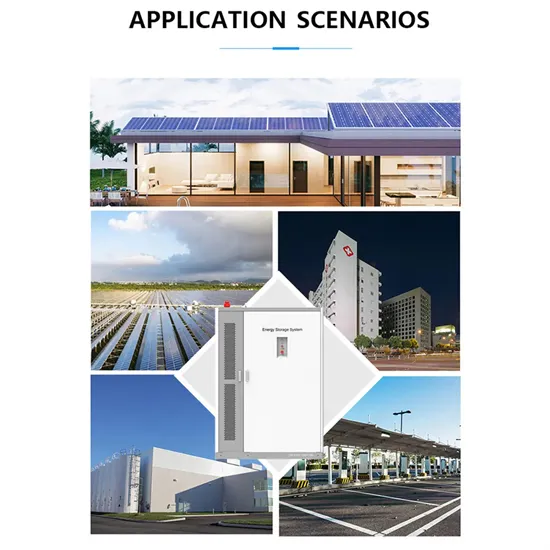

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.