Indirect liquid-cooled lithium-ion battery module with

1 day ago · Deng et al. [15] numerically studied a battery pack consisting of four batteries with liquid-cooled cold plates employing a serpentine channel, where the effect of different

Liquid Metal-Enabled Synergetic Cooling and Charging of

Apr 1, 2025 · This unit connects the EVs and charging stations, facilitating the transfer of electrical energy from the grid power to the vehicle battery. The induction electromagnet-driven unit

How Liquid-Cooled Charging Piles Are Revolutionizing EV

4 days ago · Today, there are three main types of charging, with a fourth, faster option under exploration: Liquid-Cooled Charging Piles. EV Charging Stations: Level 1 and Level 2 chargers

Liquid Cooling Solutions in Electric Vehicles

Apr 14, 2022 · Overview This paper addresses current and upcoming trends and thermal management design challenges for Electric Vehicles and eMobility with a specific focus on

What to Know in Liquid Cooling for Electric Vehicle

Oct 28, 2021 · Given the limitations of existing air-cooling solutions, liquid cooling is a logical next step for enabling eficient performance of onboard battery cells/ packs, charging stations and

Liquid Metal-Enabled Synergetic Cooling and Charging of

Apr 1, 2025 · High-power direct current fast charging (DC-HPC), particularly for megawatt-level charging currents (≥ 1000 A), is expected to significantly reduce charging time and improve

Optimal design of liquid cooling structures for superfast charging

Jan 1, 2024 · The advancement of electric vehicle technologies powered by lithium batteries integrates achievements of coordinated development of various key techniques, such as the

Liquid-cooled energy storage battery charging station

Why do EV charging stations use green coolants? liquid cooled technology is environmentally friendly. Boyd cooling systems are built in-region for EV charging station infrastructu e

A state-of-the-art review on numerical investigations of liquid-cooled

Nov 10, 2024 · The battery thermal management system (BTMS) is an essential part of an EV that keeps the lithium-ion batteries (LIB) in the desired temperature range. Amongst the different

Liquid-cooled energy storage battery charging station

What is a semi-liquid cooled charging station? From a perspective rooted in technological security,traditional charging stations or semi-liquid-cooled charging stations employ air cooling

New Nissan Leaf Adds Liquid Cooling for Better Battery Life

Jun 19, 2025 · A Major Change After 15 Years For the first time since its 2010 debut, the Nissan Leaf is ditching its outdated air-cooled battery. That setup relied on air flow to manage battery

What Is Battery Liquid Cooling and How Does It

5 days ago · Batteries are cooled by a liquid-to-air heat exchanger that circulates cooling fluids through the battery cells. The coolant is a mixture of water and

中国科大研发出室温液态金属基新型超快充液流电池

Dec 20, 2024 · 相关成果以题为"High-Performance Liquid Metal Flow Battery for Ultrafast Charging and Safety Enhancement"的论文发表在《先进能源材料

Why Liquid Cooling Is the Future of High-Power EV Chargers

Mar 21, 2025 · Liquid-cooled chargers keep temperatures low, allowing for continuous, full-speed charging without throttling. This is essential as EV batteries get larger and demand faster

中国科大研发出室温液态金属基新型超快充液流电池

Dec 20, 2024 · 近日,中国科学技术大学工程科学学院热科学和能源工程系特任教授谈鹏团队在液流电池领域取得重要突破,为电动汽车储能技术的发展提供了

AC/DC Liquid Cooling Charging Module Market

Aug 19, 2025 · For instance, automakers like Porsche implementing 800V architectures rely heavily on high-power liquid-cooled modules (often 400kW+) in their flagship charging

Liquid-cooled Ultra-fast Charging | EV Fast Charging

Discover the power of Liquid-Cooled Ultra-Fast Charging technology, designed to deliver faster, more efficient EV Fast Charging solutions for modern electric vehicles. Enhance your driving

6 FAQs about [Liquid-cooled charging stations and flow batteries]

What is a liquid cooling charging module?

The liquid cooling module is the core of the liquid cooling charging system, and the heat dissipation principle: the coolant is driven by the water pump to circulate between the inside of the liquid cooling charging module and the external radiator, taking away the heat of the module.

Why do EV charging systems need liquid cooling?

Along with increased charging speed and higher heat, the resulting cables can become bulky and unwieldy. High-power EV charging solutions require the benefits of liquid cooling. Compared to standard air cooling, liquid cooling offers more efficient heat dissipation — the key to unlocking higher performance and shorter charging times.

What is a liquid cooled charging cable?

Liquid-cooled charging cables, on the other hand, use thinner wires and liquid cooling technology to effectively reduce the temperature at the DC contacts of the cable and vehicle electrical connectors, while also making the cables lighter and easier to handle and use.

Why is liquid cooling a logical next step?

Given the limitations of existing air-cooling solutions, liquid cooling is a logical next step for enabling eficient performance of onboard battery cells/ packs, charging stations and other key EV components such as charging cables. All must be able to handle the heat as power increases.

How does air cooling work in EV charging stations and battery cyclers?

Air and liquid cooling are the primary methods for dissipating excess heat in EV charging stations and battery cyclers. Air cooling, favored for its simplicity and cost-effectiveness, is commonly used in ac chargers.

What is a liquid cooling system?

(Image: CEJN Industrial) Widely deployed in industrial settings, liquid cooling systems are now popular for high-power, ultra-fast EV charging stations and battery cyclers. Without proper cooling, power converters in 150-kW fast dc chargers can experience temperature rises exceeding 200° C during a 10-minute charge.

Learn More

- Review opinions on liquid flow batteries for communication base stations

- Charging and discharging of energy storage batteries in photovoltaic power stations

- How many liquid flow batteries are there in China s communication base stations

- How to avoid liquid flow batteries in communication base stations

- Secondary overcurrent protection for flow batteries in communication base stations

- Replacing batteries in energy storage power stations

- Safety standards for wind-solar hybrid batteries for communication base stations

- How to install lead-acid batteries in communication base stations

- Flow batteries need to flow

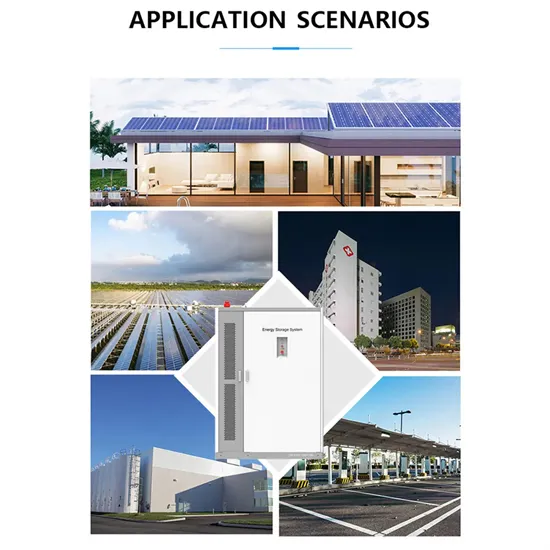

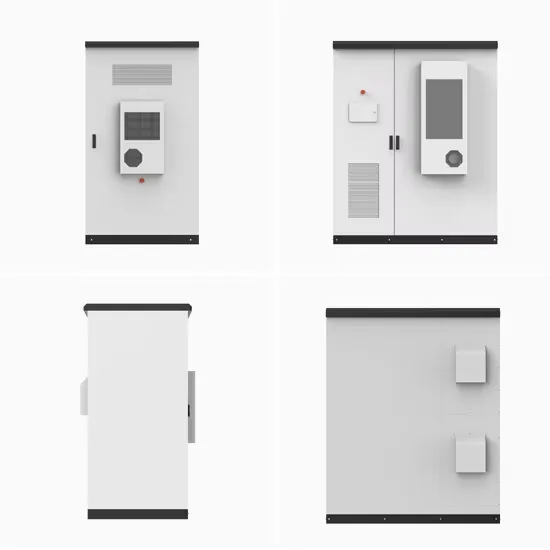

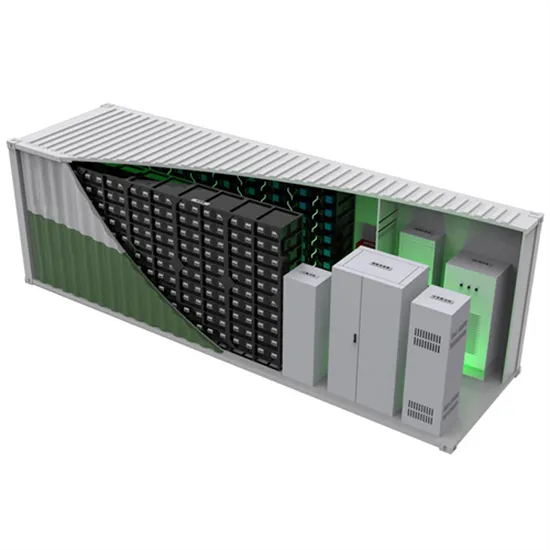

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.