PV Containerized Substation-Xiamen Minghan Electric Co., Ltd.

The PV containerized substation is a pre-Prefabricated booster substation integrating a low-voltage switchgear system, a high-voltage switchgear system, transformers, and auxiliary

What Certifications Should Solar Containers Have? A Buyers''

Jun 26, 2025 · What certifications should solar containers have? Learn the key standards like IEC, UL, CE, and UN38.3 that ensure safety, compliance, and international deployment success.

9_Containerised Substation

Mar 14, 2016 · Containerised solar substation are designed for clustered solar parks where space and safety is a concern, GENERAL and are DETAILS of capacity 500KW to 20MW projects.

C&I PV System Safety White Paper

A PV system involves various safety risks to PV equipment, asset in surrounding environments, and personal safety of O&M and firefighting personnel. With the popularization of high-power

Safety Operation Guidelines for Container Substation

Aug 15, 2025 · All personnel working with or near the container substation must wear appropriate PPE. This includes insulated gloves, safety glasses, arc-flash rated clothing, and non

Containerised Substations

4 days ago · Today''s global power suppliers are under increasing pressure to reduce operational costs and pass on savings to end customers. An area where primary cost savings can be

photovoltaic energy storage in container substation

Optimal planning of HV/MV substation locations and sizes considering battery energy storage In light of recent advancements in energy storage technology, this paper introduces a

Usage Guidelines for Best Container Type Substation

Aug 14, 2025 · The Best Container Type Substation should be installed on a level, stable foundation with adequate drainage. Ensure sufficient clearance around the unit for

What is a Containerised substation?

High safety and convenient maintenance: The shell of the container substation is made of high-strength steel plate, which has good fireproof, anti-theft, anti-small animal, rainproof, dustproof,

Safety Protection Measures for Popular Container Type Substation

Jun 20, 2025 · Modern power distribution systems increasingly rely on prefabricated solutions for efficient energy delivery. Below details essential safety protection measures for the popular

1402-2021

Nov 9, 2021 · Guidance for the physical security of electric power substations is provided in this guide. It addresses a number of threats, including unauthorized access to substation facilities,

Prefabricated Substation

May 6, 2025 · The Integrated Photovoltaic Containerized Substation is a cutting-edge, all-in-one solution designed to streamline solar energy generation, grid integration, and energy

Precautions for Using Container Type Substation_Huaquan

May 6, 2025 · A Container Type Substation is a highly efficient and compact power distribution solution, but proper usage and maintenance are crucial to ensure safety and longevity. Here

Medium voltage containerised power substations -Varelen

Medium voltage containerised power substations for the solar, mining, tunnelling and construction industries. Containers substation are offered as standard or bespoke packages to suit the

Safety Practices for Best Container Type Substation

May 29, 2025 · Before energizing the Best Container Type Substation, conduct comprehensive inspections of all components. Verify proper grounding connections, check for visible damage,

6 FAQs about [Photovoltaic container substation safety]

What are substation safety standards?

The main mission of all these regulations is safeguarding of personnel from hazards arising from the installation, maintenance or operation of substation equipment. Safety standards contain requirements for: All these measures are based on common sense and the goal to provide a safe environment for substation personnel.

Is safety a priority in substation design?

It is fair to say that safety is always a No. 1 priority in substation design, operation and maintenance. Unlike the case where a higher reliability required a larger investment, we can’t put a price tag on safety since there is no such thing like working conditions being more or less safe.

What are the risks associated with a PV system?

A PV system involves various safety risks to PV equipment, asset in surrounding environments, and personal safety of O&M and firefighting personnel. With the popularization of high-power PV modules, DC faults bring higher equipment risks.

Are substations intended to support visitor traffic?

Substations are not intended to support visitor traffic. It is possible to prevent or reduce the possibility of accidents by either restricting or totally prohibiting visitors from entering the place. In unavoidable circumstances, visitors accompanied by experienced personnel can be allowed access, but with the necessary safety precautions and PPE.

Are substations dangerous?

Substations also tend to double up as storage for equipment and other material that find use in the environment, leading to at least a couple of unwarranted risks. It not only increases footfall in the area as materials get shifted in and out of the facility, but also lures thieves on the lookout for expensive electrical components/ equipment.

How to design a safe PV plant?

Therefore, the safety design of a PV plant needs to consider the equipment, asset, and personal safety. A systematic solution design is required to build a truly safe and reliable PV plant. To address the preceding safety challenges, the industry has developed some solutions.

Learn More

- The role of Bulgaria s Sykvo photovoltaic folding container substation

- Bissau photovoltaic container substation style

- Poland photovoltaic container substation is beautiful

- Kiribati Photovoltaic Integrated Container

- North Africa Small Solar Photovoltaic Folding Container Liquid Cooling

- Juba container photovoltaic energy storage

- High power photovoltaic panels for safety

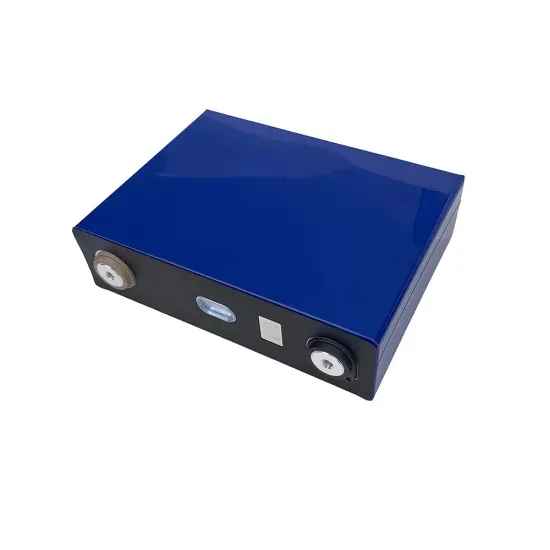

- How to view batteries in photovoltaic container systems

- Photovoltaic energy storage container cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.