Ultimate Guide to Battery in Inverter: Choose & Maintain Right

Jul 7, 2025 · Discover how to choose, maintain, and maximize your battery in inverter for reliable backup power. Expert tips on inverter batteries, lifespan, and safety included!

How long will an inverter run off a battery? –

Feb 12, 2025 · Additionally, regularly cleaning inverter cooling vents and maintaining the battery at an optimal temperature of 15°C to 25°C can reduce

Common Home Inverter and Battery Issues: Causes and

Mar 4, 2025 · In this guide, we''ll cover the most common inverter issues, their causes, and how to fix them effectively. Causes: Loose or corroded battery terminals. Old or damaged battery.

Solar battery efficiency and conversion losses

Aug 7, 2025 · Assuming the inverter has an efficiency of 96 per cent for charging and discharging and the batteries have the same, the calculation is as follows:

How Do Inverter Efficiency and Battery Health Affect Runtime?

Oct 29, 2024 · Inverter efficiency and battery health are critical factors that directly impact the runtime of any system relying on battery power. A highly efficient inverter maximizes energy

Does An Inverter Drain The Battery Overnight? Exploring Power Inverter

Feb 19, 2025 · An inverter can drain a battery if used without the engine running. It draws power from the battery, reducing its levels. To prevent this drain, monitor battery levels and use the

How exactly does grid-tied hybrid inverter detect loss of grid?

Aug 17, 2022 · So, I''ve just got a 2nd inverter going and was pondering how an inverter knows the grid is disconnected (within a few hundred milliseconds)? And, specifically, how does that work

What is Inverter Clipping and How to Avoid It?

Feb 17, 2025 · Inverters can suffer from clipping when in use, and it is essential to address this issue. In this post, we''ll examine inverter clipping, how it affects

Is there a formula to figure out power loss of a power inverter?

Feb 15, 2015 · It definetely depends on the inverter you use. Most (probably all) of them have a couple of efficeny graphs in their datasheets from which you can figure out how many power

Inverter Self-Power consumption / efficiency

Sep 29, 2023 · I do have an H3 Foxx inverter, 6,5 kWp Solar and 8,5 kWh battery setup. Inverter is described with 95% or more efficiency, but real data do show something very different.

Battery Draining if Inverter Left On

Nov 29, 2020 · Inverters do consume some power even at idle. Some use more than others. Some have settings that allow them to use a little less than normal. Your battery is 12V 100Ah

How Much Power an Inverter Draws with No Load

To find out how much power an inverter draws without any load, multiply the battery voltage by the inverter no load current draw. A 1000 watt 24V inverter with a 0.4 no load current has a

Are Large Inverters Less Efficient?

Do not use the inverter in any way the user guide does not recommend. If you follow the instructions, the system will run fine. Use an efficient battery bank. In an off grid system, the

Common Home Inverter Problems and How to Fix Them

Jan 21, 2025 · Learn about the most common home inverter problems and how to fix them. From battery issues to inverter malfunctioning, this guide provides easy solutions to keep your home

What percentage of losses occur in conversion

May 19, 2017 · Nothing seems out of order. In an inverter/charger system, you have two primary sources of inefficiency: the battery charging circuit that must

Can An Inverter Damage A Battery? Risks, Safety Concerns,

Feb 8, 2025 · An inverter can damage a battery if used incorrectly. Key factors include installation quality, compatibility with the battery type, and maintenance. To minimize risks, ensure proper

6 FAQs about [Does the battery inverter have any loss ]

What are the problems with Inverter Batteries?

Inverter batteries can face several problems. Identifying these issues early helps in battery management. Here are some common problems: Overcharging: This can damage the battery. It reduces its life. Undercharging: The battery doesn’t get enough charge. It affects performance.

What happens if a power inverter goes out?

The inverter remains in battery mode until the grid supply is restored. Once the mains return, it automatically reverts to charging mode to replenish the battery in inverter. During prolonged outages, efficient power usage becomes essential to prevent rapid battery drain.

Do inverters need batteries?

For most residential and small commercial setups, the traditional battery and power inverter combo is the preferred choice to ensure continuous power supply during blackouts. So, while some inverter types do not require batteries, if your priority is uninterrupted backup power, investing in a quality battery in inverter system is essential.

Why are Inverter Batteries important?

Inverter batteries are crucial for power backup. They need proper care. Battery management ensures they last longer and perform well. You can avoid frequent replacements. Let’s explore more about keeping your inverter battery healthy. Healthy batteries provide consistent power supply. They reduce chances of sudden power loss.

How long do Inverter Batteries last?

Battery backup duration varies based on battery capacity, load, and battery health. A typical 150Ah tubular inverter battery running a moderate load of lights and fans can last between 4 to 6 hours. Heavy appliances or higher load will reduce this time.

What should I do if my power inverter is not working?

Use Energy-Efficient Appliances: Replace older, power-hungry appliances with energy-efficient models that draw less power from your battery and power inverter system. Regularly Monitor Battery Voltage: Use a voltmeter or inverter display to check battery health and avoid deep discharges.

Learn More

- How much battery loss after passing through the inverter

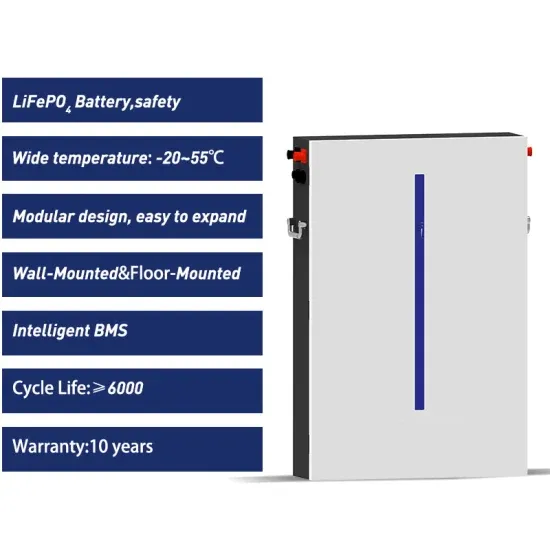

- Lithium phosphate battery connected to inverter

- Can a 11 6 volt battery drive an inverter

- Inverter Super Battery

- Battery inverter modification

- Battery inverter 36v to 220v

- Car battery connected to inverter

- Amorphous machine inverter battery

- The role of battery plus inverter

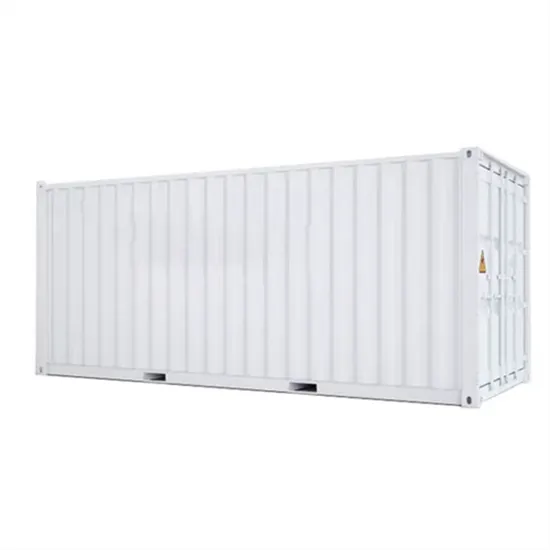

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.