12v To 220v 100w Inverter Circuit Diagram

Sep 24, 2017 · Whether you are a seasoned electrical engineer or someone just starting out in the field of electronics, the 12v To 220v 100w Inverter Circuit Diagram is an essential item to have

100 Watt Inverter Circuit 12V to 220V using Transistor

Apr 12, 2022 · It will induce electrical energy through the metal core from a set of 12V coils to an AC voltage of 220V at 50Hz to 60Hz for further use. you want 100 watts, so must use an 8A

100 watt 12v DC to 220v AC Inverter Circuit Diagram

May 24, 2016 · Today we are going to build a 100 watt 12v DC to 220v AC inverter. This Circuit is simple and very useful. 12v-0-12v 10Amp Step down transformer: IRF540N MOSFET should

100 watt inverter | 12v to 220v inverter | 12v to 220

100 watt inverter | 12v to 220v inverter | 12v to 220 converter | dc to ac inverter | mini inverter Is video mein humne test kiya hai 100 Watt Inverter (12V to 220V Converter) jo easily DC battery

Multifunction Inverter 100W DC 12V to AC 110/220V + USB 5V Car Inverter

It can convert DC 12V electricity provided by the automobile into AC power Widely used with that electric equipment whose power consumption are less than 100W, such as notebook,

DC 12V to AC 220V 100W Auto Car Power Inverter Charger

DC 12V to AC 220V 100W Auto Car Power Inverter Charger Supply Adapter ConverterFeatures: Plug and play, with car cigarette lighter, convert 12V to 220V and charge for all kinds of

How to Build 100 Watt 12v DC to 220v AC Inverter Circuit

UPS is a system which converts DC to AC. So, UPS takes DC power of battery as input and gives AC power as output. Today we are going to build a 100 watt 12v DC to 220v AC inverter with

ERHIndia 100 Watt Dc to Ac Mini Inverter for Multiple

Buy ERHIndia 100 Watt Dc to Ac Mini Inverter for Multiple Applications 12v to 220v Pure Sine Wave Inverter for Rs. online. ERHIndia 100 Watt Dc to Ac Mini Inverter for Multiple

6 FAQs about [100w inverter becomes 220v]

What is a 100 watt inverter circuit?

They are devices that turn your vehicle battery’s direct current (DC) into alternating current (AC). It increases the DC voltage and changes it to AC, then uses it to power your devices. It can be converted from 12V DC to 220V AC. The maximum output power is about 100 watts. The following components are required to make 100 Watt Inverter Circuit 1.

How to make a 12V DC to 220V AC inverter circuit?

So every time a pulse reaches the MOSFET gate, we will have a 220V half cycle at the output. In the next pulse, the second MOSFET triggers for the second half cycle of 220V. So with two MOSFETS turning on and off at 50Hz frequency, we will have 50Hz 220V cycle output at the transformer end. So we have made a 12V DC to 220V AC Inverter Circuit.

What IC to use for 100W inverter?

This is the inverter 100W circuit, use IC 4047 alike inverter 100W transistor I use MOSFET IRF540 instead Transistor 2N3055. It good Idae, power output 100W from transformer 2-3A. Read detail more in circuit. How to use CD4047 Monostable Astable Multivibrator IC The 12V battery comes into the circuit.

What are the parts of a 100W inverter circuit?

Figure 1, 100w Inverter circuit, 12V to 220VAC using transistors This circuit will include five main sections as a block diagram. 1. Q1 and Q2 act as the frequency oscillator circuit. 2. Q3 and Q4 act as the frequency divider circuit 3. Q5 and Q6 act as the transistor driver circuit. 4. Q7 and Q8 act as the output power amplifier circuit.

What is AC inverter?

This is AC Inverter. Input 12VDC from car battery to output 220V AC 50Hz or 60Hz at Square wave signal. The main part is CD4047 (or IC 4047 Series) and IC-LM358 and Transistor 2SC1061 and 2N3055. The transformer is 10V-CT-10V, Primary : 220V Secondary. and current 3A up for power output than 100W. C1 = 0.1uf metalized-film capacitor, 5% tolerance.

What type of inverter is used in everyday life?

The most common type of inverter we see in everyday life is UPS (Uninterruptible Power Supply). We use UPS to keep PC (Personal Computer) running in the event of power cuts. UPS keeps up the power delivered until battery bank runs out. UPS is a system which converts DC to AC. So, UPS takes DC power of battery as input and gives AC power as output.

Learn More

- 220v down to 36v inverter

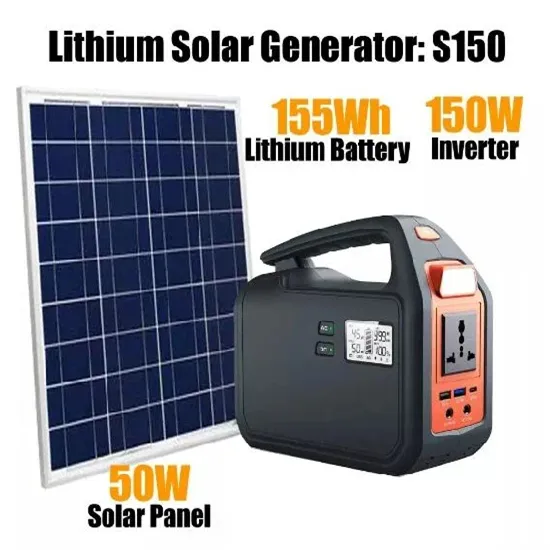

- Inverter 12v to 220v solar energy

- Wholesale 220v solar inverter in Switzerland

- Wholesale 220v solar inverter in Vancouver

- 3v to 220v DC inverter production

- Wholesale 220v solar inverter in Brunei

- Battery inverter 36v to 220v

- DC 96v inverter 220v ups

- Ulaanbaatar 220v inverter

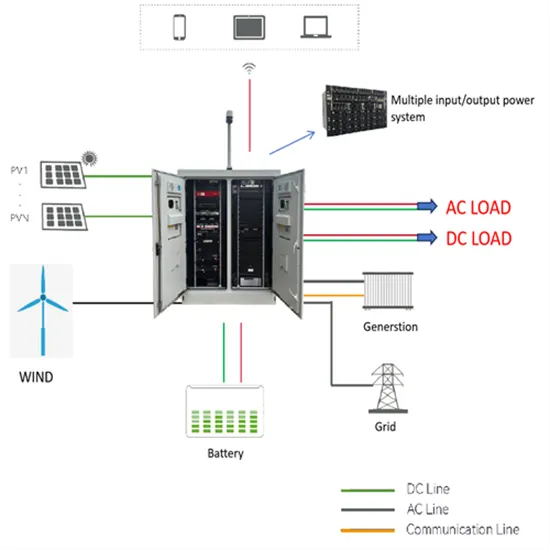

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.