Configuring PWM Outputs of TMS320F240 With Dead

Apr 1, 2023 · The DSP controller TMS320F240 has a programmable dead band generator to insert a dead band between two PWM outputs (PWM1&2, PWM3&4, and PWM5&6). The

TMS320F/C24x DSP Controllers Reference Guide

Aug 6, 2011 · TMS320C240, TMS320F240 DSP Controllers (literature number SPRS042) data sheet contains the electrical and timing specifications for these devices, as well as signal

"Switched Reluctance Motor Control

Apr 26, 2014 · ABSTRACT This report describes the basic operation of switched reluctance motors (SRMs) and demonstrates how a TMS320F240 DSP-based SRM drive from Texas

Deye energy source priority setting

Sep 26, 2023 · Some other chinese inverters like the Easun have the SBU mode (solar-battery-utility priority) which is pretty self explanatory, but for the Deye I''m having a hard time figuring

TMS320F/C24x DSP Controllers Reference Guide

Aug 6, 2011 · TMS320C240, TMS320F240 DSP Controllers (literature number SPRS042) data sheet contains the electrical and timing specifications for these devices, as well as signal

FOC FOR SYNCHRONOUS MOTOR ON TMS320C2XX

Apr 1, 2023 · High range controls increase system performance, reliability, efficiency, and cost. This application report describes a speed control implemented on a TMS320F240 for a three

Inverter AC Battery Priority Question

Oct 29, 2022 · I can use a relay to disconnect the AC input from the inverter to force it to run on battery when desired, and leave the inverter on AC priority. I can use relay logic with some

Inverter AC Battery Priority Question

Oct 29, 2022 · The inverters that I have seen have a dip switch to switch between AC and battery priority, but I either need external control of this (hopefully without opening op the inverter and

DSP SOLUTIONS FOR MOTOR CONTROL USING THE

Apr 1, 2023 · Digital Signal processing technology is enabling cost effective and energy efficient control system design. The performance of a DSP architecture allows an intelligent approach

TMS320F240 DSP Controller (Rev. E)

Nov 1, 2022 · The TMS320F240 (F240) device is a member of a family of DSP controllers based on the TMS320C2xx generation of 16-bit fixed-point digital signal processors (DSPs). This

FOC FOR SYNCHRONOUS MOTOR ON TMS320C2XX

Apr 1, 2023 · Figure 3 shows the inverter topology used. All of the power device securities are wired (Shutdown, Fault, Clearfault, Itrip, reverse battery diode, varistor peak current

TMS320F240 DSP Controller datasheet (Rev. E)

Sep 24, 2018 · XINT3 can be used as a high-priority (Level 1) or low-priority (Level 6) maskable interrupt or as a general-purpose I/O pin. XINT3 can also be programmed to trigger an

TMS320F240PQ引脚图及功能_参数_微控制器芯片中文资料

TMS320F240PQ TI 微控制器芯片中文资料PDF, 共 (105)页, TMS320F240PQ数据手册有芯片封装BQFP-132引脚图及功能定义和参数资料, DSP控制器 DSP CONTROLLER。

C240 DSP Controllers Peripheral Library and Specific

Aug 6, 2011 · TMS320F240 DSP Controller (literature number SPRS042) data sheet contains the electrical and timing specifications for the TMS320F240 device, as well as signal descriptions

Why inverter need Inverter battery priority unattended?

When the battery voltage returns to the set parameters, the inverter will automatically turn on without us having to turn it on。 Inverter battery priority unmanned operation refers to a

Setting Victron Multiplus II to work like EG4 SUB

Aug 14, 2022 · The inverters favor the grid power when in SUB because it''s more stable. It actually seems like it might be more efficient the way the Victron runs

Incremental Encoder I/F Plus Interpolation

Apr 1, 2023 · The section, Incremental Rotary Encoders, describes the principle of sin/cos-encoders and the method to obtain high-resolution position. The section, Implementation on

TMS320F/C240 DSP Controllers Peripheral Library and

Aug 6, 2011 · TMS320F240 DSP Controller (literature number SPRS042) data sheet contains the electrical and timing specifications for the TMS320F240 device, as well as signal descriptions

Why inverter need Inverter battery priority unattended?

An inverter with battery priority is a type of power inverter that allows a battery bank to take precedence over an external power source. This means that if the battery bank is charged and

6 FAQs about [Tms320f240 inverter battery priority]

What are the tms320f240 low power modes?

The TMS320F240 has four low-power modes (IDLE 1, IDLE 2, PLL power down, and oscillator power down). The low-power modes reduce the operating power by reducing or stopping the activity of various modules (by stopping their clocks).

How does the tms320f240 power board work?

All of the power device securities are wired (Shutdown, Fault, Clearfault, Itrip, reverse battery diode, varistor peak current protection). The current sensing is insured by 2 L.E.M. directly interfaced with the TMS320F240. The power board also supports the voltage supply of an incremental encoder.

What is tms320f240?

The DSP-Controller TMS320F240 combines the performance of DSP architecture with the optimized peripherals of a Microcontroller. With the DSP-Controller an intelligent control approach is possible to reduce the overall system costs and to improve the reliability of the drive system.

What is the tms320f240 DSP controller data sheet?

TMS320F240 DSP Controller (literature number SPRS042) data sheet contains the electrical and timing specifications for the TMS320F240 device, as well as signal descriptions and pinouts for all of the available packages.

What is tms320f240 memory map?

TMS320F240 Memory Map The TMS320F240 system and peripheral control register frame contains all the data, status, and control bits to operate the system and peripheral modules on the device (excluding the event manager).

How does tms320f240 emulation work?

TMS320F240 device uses scan-based emulation for code- and hardware-development support. Serial scan interface is provided by the test-access port. Scan-based emulation allows the emulator to control the processor in the system without the use of intrusive cables to the full pinout of the device.

Learn More

- What inverter to use for a 2 volt battery

- Inverter battery control cabinet

- 100a lithium battery inverter

- Does the inverter size have anything to do with the battery

- Battery and inverter charging in Bosnia and Herzegovina

- Pure sine inverter with lithium battery

- Lithium battery 12v inverter power supply

- How many times of battery is needed for the inverter

- Lithium battery integrated inverter outdoor power supply

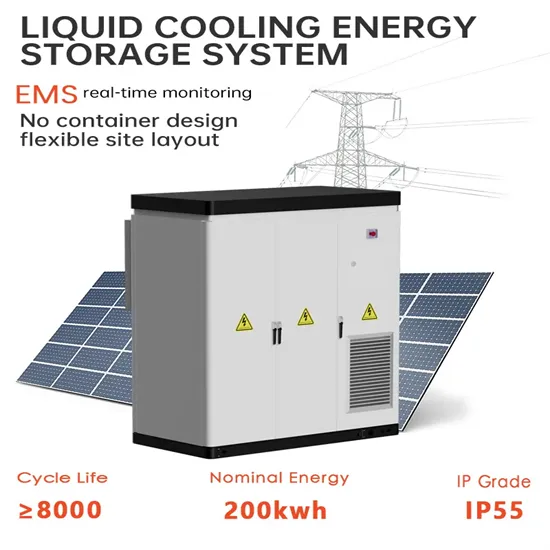

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.