Journal of Energy Storage

Dec 15, 2022 · Supercapacitors have received wide attention as a new type of energy storage device between electrolytic capacitors and batteries [2]. The performance improvement for

Loss Analysis of Hybrid Battery-Supercapacitor Energy

Oct 10, 2024 · Therefore, dynamic performance of the EV with hybrid battery-supercapacitor energy storage system can be better than the EV with battery energy storage system. In

Supercapacitors: An Efficient Way for Energy

Feb 1, 2024 · To date, batteries are the most widely used energy storage devices, fulfilling the requirements of different industrial and consumer applications.

Life prediction of on-board supercapacitor energy storage

Feb 1, 2025 · With the increasing use of supercapacitor in transportation and energy sectors, service life prediction becomes an important aspect to consider. As th

Loss and Energy Determination of a 400kW Grid-Connected Supercapacitor

Oct 18, 2023 · This paper presents a 400 kW grid-connected supercapacitor energy storage system. The losses of the active Front End including an LCL filter, the DC/DC converte

Review of battery-supercapacitor hybrid energy storage

Dec 1, 2024 · The potential of using battery-supercapacitor hybrid systems. Currently, the term battery-supercapacitor associated with hybrid energy storage systems (HESS) for electric

ENERGY STORAGES IN HIGH-POWER STATCOM

Jun 28, 2022 · In addition, the size, complexity and cost should be minimal. Supercapacitors, Li-ion batteries, superconducting magnetic energy storages, flywheels and Li-ion capacitors were

Super capacitors for energy storage: Progress, applications

May 1, 2022 · Nowadays, the energy storage systems based on lithium-ion batteries, fuel cells (FCs) and super capacitors (SCs) are playing a key role in several app

Supercapacitors for energy storage applications: Materials,

Dec 25, 2024 · The integration of supercapacitors with other energy storage and harvesting technologies offers potential for creating more efficient and versatile energy systems.

Energy Loss Analysis of the Stationary Battery-Supercapacitor

Oct 17, 2019 · This paper proposes an energy loss analysis method for a stationary battery-supercapacitor hybrid energy storage system (HESS) in the case of regenerative braki

Loss analysis of hybrid battery-supercapacitor energy storage system

Dec 14, 2017 · In this study, the losses of the hybrid energy storage system (HESS) including super-capacitor (SC) and battery in an electric vehicle (EV) are analyzed. Based on the

Hierarchical Optimization of an On-Board

Sep 4, 2020 · In order to completely replace the on-board brake resistor, this paper configures a certain on-board super-capacitor, and based on a DC-side series super-capacitor topology,

Solving Energy Loss in Supercapacitive Energy Storage

Oct 25, 2024 · Scientists in supercapacitor industry believe it is an Fe2+/3+ shuttle mechanism which is discharging the cell. No systematic studies in the literature to support this. SD with

Recent advancement of supercapacitors: A current era of supercapacitor

Feb 1, 2025 · Supercapacitors are promising energy devices for electrochemical energy storage, which play a significant role in the management of renewable electric

Supercapacitors: A Brief Overview

Nov 8, 2022 · hierarchy of supercapacitor energy storage approaches. Then, Section 4 presents an analysis of the major quantitative modeling research areas concerning the optimization of

Energy Loss Analysis of the Stationary Battery-Supercapacitor

Oct 17, 2019 · This paper proposes an energy loss analysis method for a stationary battery-supercapacitor hybrid energy storage system (HESS) in the case of regenerative braking

Multi-objective optimization of a semi-active battery/supercapacitor

Dec 15, 2014 · This paper proposes a semi-active battery/supercapacitor (SC) hybrid energy storage system (HESS) for use in electric drive vehicles. A much smaller u

Hierarchical Optimization of an On-Board Supercapacitor Energy Storage

Jan 17, 2020 · In order to absorb the regenerative braking energy of trains, supercapacitor energy storage systems (ESS) are widely used in subways. Although wayside ESS are widely used,

Supercapacitors: Overcoming current limitations and

Jan 25, 2025 · Electrochemical energy storage systems, which include batteries, fuel cells, and electrochemical capacitors (also referred to as supercapacitors), are essential in meeting

Supercapacitors for renewable energy applications: A review

Dec 1, 2023 · However, batteries suffer from a drawback in terms of low power density. In recent years, supercapacitor devices have gained significant traction in energy systems due to their

Analysis of Energy Loss and Heat Generation Characteristics

Oct 10, 2024 · The study shows that (a) for an EV with a hybrid battery-supercapacitor energy storage system the super-capacitor current can be optimized to have the minimum battery

6 FAQs about [Supercapacitor energy storage loss]

How can supercapacitors be used as energy storage?

Supercapacitors as energy storage could be selected for different applications by considering characteristics such as energy density, power density, Coulombic efficiency, charging and discharging duration cycle life, lifetime, operating temperature, environment friendliness, and cost.

How a Supercapacitors combined battery energy storage system works?

They conclude that the supercapacitors combined battery energy storage systems in wind power can accomplish smooth charging and extended discharge of the battery. At the same time, it reduces the stress accompanied by the generator.

How can Supercapacitors compete with traditional energy storage technologies?

Scaling up production and reducing manufacturing costs to compete with traditional energy storage technologies pose challenges for the widespread adoption of supercapacitors, requiring innovations in synthesis, processing, and manufacturing techniques.

What is a supercapacitor based on?

A supercapacitor has owned some internal resistance, resulting in energy loss. It can be modeled as a system consisting of a capacitor in series with a resistor (RES), as depicted in Figure 10. The RES is the resistance of the electrochemical capacitors and is important in reflecting the energy efficiency and power performance of supercapacitors.

Are supercapacitors a pivotal energy storage solution?

Emphasizing the dynamic interplay between materials, technology, and challenges, this review shapes the trajectory of supercapacitors as pivotal energy storage solutions.

Can micro-supercapacitor energy storage be used in healthcare devices?

High demand for supercapacitor energy storage in the healthcare devices industry, and researchers has done many experiments to find new materials and technology to implement tiny energy storage. As a result, micro-supercapacitors were implemented in the past decade to address the issues in energy storage of small devices.

Learn More

- Huawei Energy Storage Power Station Supercapacitor

- 21v240wf supercapacitor energy storage system

- Bulgaria energy storage supercapacitor price

- What is an energy storage supercapacitor

- Grid-side energy storage loss

- Supercapacitor energy storage uninterruptible power supply

- Energy storage battery supercapacitor

- Luanda Energy Storage Supercapacitor

- Supercapacitor flywheel energy storage

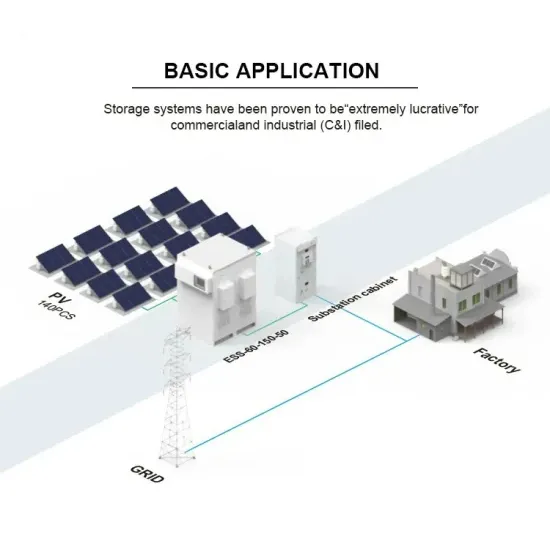

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.