Power Supply for Base Station Market

How do regional variations in 5G deployment strategies impact the power supply requirements for base stations? Regional differences in 5G rollout approaches directly influence power supply

MOTOROLA 1154A Base Station Power Supply Tpn

Jul 28, 2025 · In summary, the Motorola 1154a Base Station Power Supply TPN is a reliable, versatile, and safe power supply solution for your Motorola base station. Its robust design,

5G infrastructure power supply design considerations (Part II)

May 19, 2021 · Currently, power supply solutions deliver sufficient power to keep 4G core nodes operating. However, they may not be sufficient for 5G. Data show, for instance, that the

5G macro base station power supply design strategy and

Oct 24, 2024 · For macro base stations, Cheng Wentao of Infineon gave some suggestions on the optimization of primary and secondary power supplies. "In terms of primary power supply, we

Building better power supplies for 5G base stations

May 25, 2025 · Building better power supplies for 5G base stations Authored by: Alessandro Pevere, and Francesco Di Domenico, both at Infineon Technologies Infineon Technologies -

Selecting the Right Supplies for Powering 5G Base Stations

As a result, a variety of state-of-the-art power supplies are required to power 5G base station components. Modern FPGAs and processors are built using advanced nanometer processes

Communications System Power Supply Designs

Apr 1, 2023 · Voice-over-Internet-Protocol (VoIP), Digital Subscriber Line (DSL), and Third-generation (3G) base stations all necessitate varying degrees of complexity in power supply

Maintenance of communication base station power supply

This article discusses how to improve the power supply safety of the power supply system of communication base stations, reduce the failure rate of the power supply system of

QUANTAR Base Station/Repeater for VHF Data Sheet

Aug 7, 2012 · Reliable solid state performance Continuous duty cycle operation Battery reverting available in event of a site power failure Self-testing eases regular maintenance Switching

ASTRO Site Equipment Data Sheet

Apr 5, 2025 · Base station channels can dynamically switch from voice to data based on the call type. ASTRO Enhanced Data optimizes the data channel for applications with a high amount

Power Supply Solutions for Wireless Base Stations Applications

In particular, MORNSUN can provide specific power supply solutions for optical communication and 5G base stations applications. In particular, MORNSUN''s VCB/VCF series of isolated 3

Integrated Micro Base Station Power Supply Market

May 4, 2025 · The US FirstNet Authority''s mobile base stations utilize power supplies with 15-minute modular replacement capability, critical for emergency deployments where 73% of

ADI Technical Article: Choosing the Right Power Supply to Power 5G Base

This series can fully meet the power supply needs of 5G base station components, including software design and simulation tools such as LTpowerCAD and LTspice. These tools simplify

Distribution network restoration supply method considers 5G base

Feb 15, 2024 · This paper proposes a distribution network fault emergency power supply recovery strategy based on 5G base station energy storage. This strategy intro

Design of mobile base station communication power supply

The reliability design of the mobile base station communication power supply system is mainly used to solve the high requirements of the communication power supply system in the special

MTR3000 Base Station/Repeater and Satellite Receiver

Nov 28, 2017 · When the MOTOTRBO MTR3000 Base Station/Repeater is used in a DC reverting system, the DC power supply must be located in the same building as the MOTOTRBO

Communications System Power Supply Designs

Apr 1, 2023 · The power factor corrected (PFC) AC/DC produces the supply voltage for the 3G Base station''s RF Power amplifier (typ. +27V) and the bus voltage for point-of-load converters.

Machine learning for base transceiver stations power failure

Dec 1, 2024 · Base Transceiver Stations (BTSs), are foundational to mobile networks but are vulnerable to power failures, disrupting service delivery and causing user inconvenience. This

6 FAQs about [Base station power supply replacement requirements]

How much power does a PSU need?

This is when the PSU is no longer powering the PA, which is the main power draw, but still needs to power other electronics. The current target for low-load efficiency is about 30 W. Some OEMs would like to see that drop to nearly 10 W.

What is a 3G base station converter?

In a 3G Base Station application, two converters are used to provide the +27V distribution bus voltage during normal conditions and power outages.

What is a low profile power supply?

Low profile power supply design usually includes printed circuit board (planar) power transformers and output inductors and surface mount input and output capacitors. Multiple output power supplies are often implemented with a multi-output flyback converter.

How much power does a PSU need during a quiescent period?

During quiescent periods—typically 5 ms to 100 ms—the PSU must minimize all load power with the basic functions of the antenna unit remaining active. It also must be able to ramp up to full power whenever the antenna wants to check for any active users within its range.

What is a preferred power supply architecture for DSL applications?

A preferred power supply architecture for DSL applications is illustrated in Fig. 2. A push-pull converter is used to convert the 48V input voltage to +/-12V and to provide electrical isolation. Synchronous buck converters powered off of the +12V rail generate various low-voltage outputs.

What voltage does a DSL power system supply?

The DSL power system may supply both higher voltage analog line drivers and amplifiers (typ. +/-12V) and several low voltage supplies required by the digital ASIC (+5V, +3.3V, +1.8V, +1.5V).

Learn More

- Base station communication power supply requirements and specifications

- Base station wind power supply capacity requirements

- Base station power supply equipment panel

- Huawei base station poe power supply

- Communication base station power supply transformation plan

- 5g base station installation with power supply

- Base station power supply converted to DC charging

- Tender for China Mobile s 5G backup base station power supply

- What is the power supply of the uwb base station

Industrial & Commercial Energy Storage Market Growth

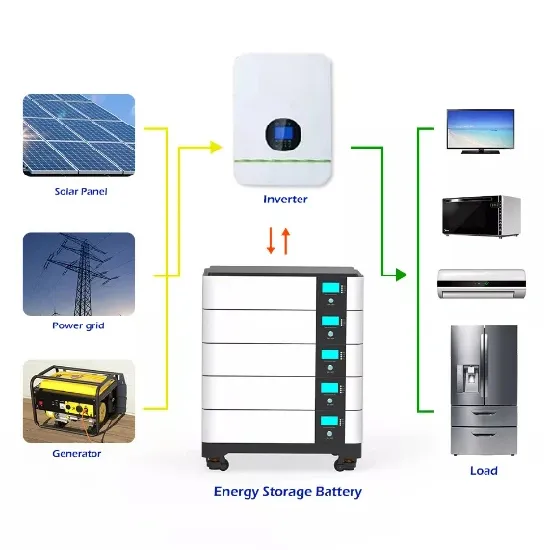

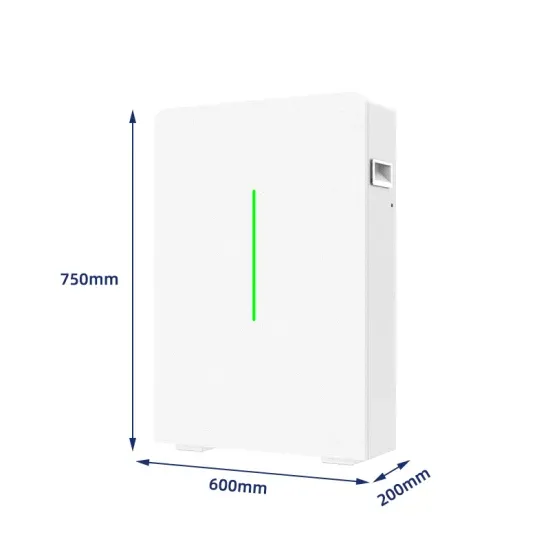

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.