Size effect on the thermal and mechanical performance of cylindrical

Dec 1, 2024 · Abstract Increasing the size of cylindrical lithium-ion batteries (LIBs) to achieve higher energy densities and faster charging represents one effective tactics in nowadays

Thermal management of cylindrical lithium-ion batteries

Jul 15, 2025 · Effective BTMS is essential to keep LIBs in their optimal operating temperature range. Efficient thermal management methods are required because research has shown that

Battery internal temperature estimation by combined

Nov 1, 2014 · A new approach, suitable for real-time implementation, is introduced for estimation of non-uniform internal temperature distribution in cylindrical lithium-ion cells. A radial 1-D

Thermal evaluation of lithium-ion batteries: Defining the cylindrical

Oct 1, 2022 · Combining geometry and the Cell Cooling Coefficient produces useful thermal metrics. A 21700 cell can dissipate heat more optimally than an 18650 cell. An 18650 pack can

Comparison on Thermal Runaway and Critical

Nov 15, 2024 · This review on the critical characteristics of cylindrical batteries under thermal failure and thermal abuse provides a reference for solving intrinsic safety issues for lithium-ion

Thermal parameters of cylindrical power batteries: Quasi

Oct 11, 2022 · In this work, a new quasi-steady state heat guarding measurement method for the thermophysical parameters of cylindrical batteries is proposed. The effectiveness of the heat

Thermal management and temperature uniformity

Jul 1, 2023 · Thermal management and temperature uniformity enhancement of cylindrical lithium-ion battery pack based on liquid cooling equipped with twisted tapes

Comparative analysis of cylindrical lithium-ion battery

Aug 1, 2025 · With the widespread application of electric vehicles, energy storage systems, and portable electronic devices, lithium-ion batteries, particularly cylindrical cells, have become a

Mitigation of cylindrical lithium ion battery thermal runaway

Feb 1, 2025 · Ensuring fire safety in Lithium ion battery (LIB) thermal runaway propagation (TRP) is a key challenge in electric vehicle battery pack design. A seri

Thermal Characterization of a Cylindrical Li-ion Battery Cell

Dec 14, 2020 · The operating temperature of Li ion batteries is one of the main aspects to consider when analysing the battery''s performance. The battery''s internal temperature in

Know your Lithium-ion Cells, Cell Specifications

Feb 4, 2021 · The article covers: Lithium-ion Cell Specifications and data sheets Important Terms related to cell/battery performance and their description

Room-temperature cylindrical lithium battery enabled by

Jun 1, 2025 · Cylindrical batteries have been explored as promising grid energy storage device, due to their high safety margin and low capital/maintenance costs. However, the practical

HANDBOOK Primary Lithium Cells (english)

May 5, 2016 · The VARTA Microbattery lithium manganese dioxide cell chemistry was one of the first solid cathode cells commercially developed and is still the most widely used system today.

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · What''s the difference between pouch, prismatic, and cylindrical cells in lithium batteries? Read our guide to find the right battery cell type for your system.

Study on the battery thermal management system for cylindrical lithium

Jul 5, 2025 · The maximum temperature of 47 °C is obtained for a pure PCM battery module at a 3 C discharge rate, and it is well matched with experimental results.

Optimal cell tab design and cooling strategy for cylindrical lithium

Apr 30, 2021 · The ability to correctly predict the behavior of lithium ion batteries is critical for safety, performance, cost and lifetime. Particularly important for this purpose is the prediction

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

General overview on test standards for Li-ion batteries,

Nov 2, 2017 · This table covers test standards for Li-ion batteries. It is made in the European projects eCaiman, Spicy and Naiades. batterystandards

In-situ temperature monitoring of a lithium-ion battery

Oct 1, 2022 · Uncertainty in the measurement of key battery internal states, such as temperature, impacts our understanding of battery performance, degradation and safety and underpins

Design, Properties, and Manufacturing of Cylindrical Li

Jul 7, 2023 · In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla

A review of lithium-ion battery safety concerns: The issues,

Aug 1, 2021 · Lithium-ion batteries (LIBs) with excellent performance are widely used in portable electronics and electric vehicles (EVs), but frequent fires and explosions limit their further and

Advanced Thermal Management of Cylindrical Lithium-Ion

Jul 25, 2024 · According to Ji et al. [9], the maximum temperature range before performance degradation for a lithium-ion battery is 253.15 K to 333.15 K, while the optimal operating range

Comparison on Thermal Runaway and Critical

Mar 3, 2025 · The thermal hazard results of commercial cylindrical lithium-ion batteries (LIBs) of different sizes from international laboratories are reviewed

Degradation behavior of 21700 cylindrical lithium-ion battery

Nov 30, 2023 · Abstract Lithium-ion battery (LIB) cells are prone to overdischarge or overcharge when connected in series or parallel as a module or pack for large-format applications, such

A new method to determine the heating power of ternary cylindrical

Oct 1, 2020 · A new method to determine the heating power of ternary cylindrical lithium ion batteries with highly repeatable thermal runaway test characteristics is proposed based on

Experimental measurement and modeling of the internal

Dec 1, 2024 · Standards may evolve to include limits on internal pressure, temperature thresholds, and mandatory real-time monitoring to detect and prevent failures early, ultimately

Temperature estimation from current and voltage measurements in lithium

Feb 1, 2021 · We propose a novel algorithm to infer temperature in cylindrical lithium-ion battery cells from measurements of current and terminal voltage. Our approach employs a dual

Development perspectives for lithium-ion battery cell

Dec 5, 2022 · As one central result, the market has witnessed a wide variety of manufacturer- and user-specific cell formats in the past. Standard formats for cylindrical cells were established

Thermal Investigation of Cylindrical Lithium-ion Batteries for

Dec 8, 2022 · Thermal investigation of cylindrical lithium-ion batteries of different chemistry and shape factors (18650 NMC and 21700 NCA) is conducted for different charging/discharging

6 FAQs about [Cylindrical lithium battery temperature standard]

Do cylindrical lithium-ion batteries have a thermal stability problem?

This work is motivated by the critical need to improve the thermal stability of cylindrical lithium-ion batteries, especially in electric vehicles and high-performance electronics, where overheating during rapid charging and high discharge rates can lead to thermal runaway and decreased lifespan.

What is the thermal investigation of cylindrical lithium-ion batteries?

Thermal investigation of cylindrical lithium-ion batteries of different chemistry and shape factors (18650 NMC and 21700 NCA) is conducted for different charging/discharging rates (0.5 C, 1 C, 1.5 C) and surrounding temperatures (26 °C and 45 °C) using numerical and experimental techniques.

Do lithium-ion batteries need thermal management?

The rapid growth of electric vehicles (EVs) and portable electronic devices has intensified the need for efficient thermal management in lithium-ion batteries (LIBs), prone to overheating and catastrophic failure if not adequately managed.

Does PCM improve surface temperature in lithium-ion batteries?

Comparative analysis of surface temperature in lithium-ion batteries: with and without PCM thermal management at 2C and 3C The principal mechanism underlying this enhanced thermal performance is PCM’s inherent capacity to absorb significant amounts of heat generated during high discharge rates.

What are the thermal parameters of cylindri-cal li-ion cells?

The methods will be developed aiming to measure the thermal parameters of cylindri-cal Li-ion cells, such as axial and radial thermal conductivities, and specific heat capacity. The main focus of this work is to experimentally determine the thermal parameters of a cylindrical Li-ion cell.

Are 18650 NMC and 21700 NCA cylindrical lithium-ion batteries thermally investigated?

In this research work, thermal investigations of 18650 NMC and 21700 NCA cylindrical lithium-ion batteries have been carried out for different charging/discharging rates and surrounding temperatures using numerical and experimental techniques.

Learn More

- Cylindrical low temperature lithium battery

- Dili Large Cylindrical Lithium Battery

- Tunisian cylindrical lithium battery

- Syria cylindrical lithium iron phosphate battery

- Ethiopia cylindrical lithium battery

- Kuwait low temperature lithium battery pack manufacturer

- Cylindrical lithium battery recommendation

- How many volts is the largest cylindrical lithium battery in Albania

- Is the Warsaw lithium battery cylindrical

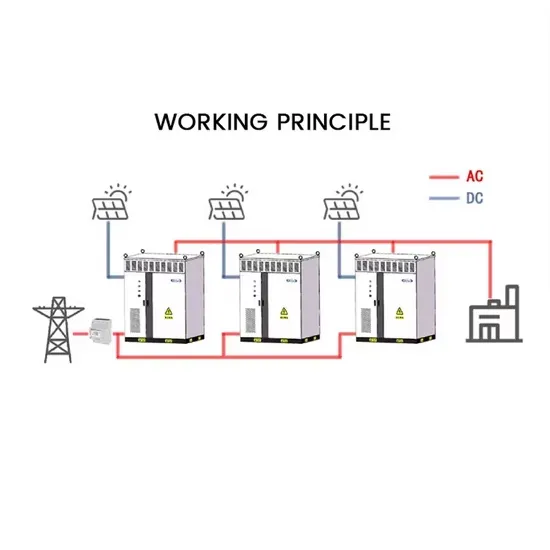

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.