How can energy storage cabinets reshape the future of

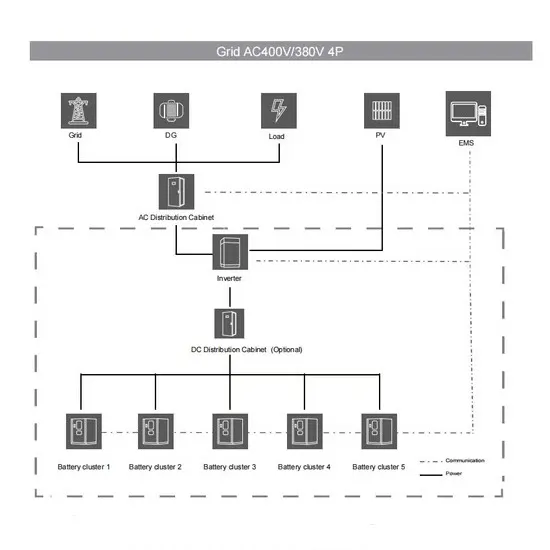

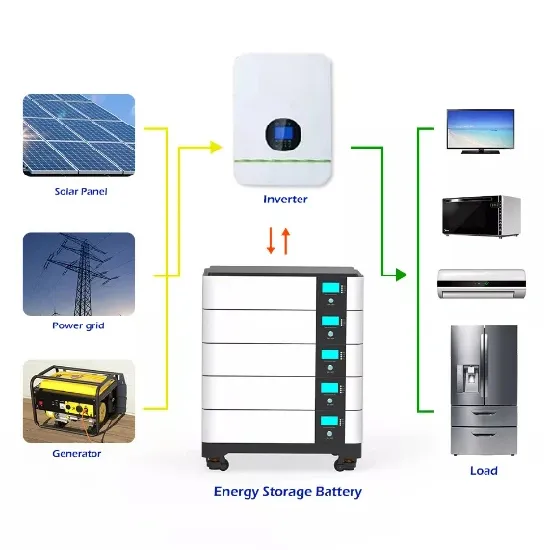

5 days ago · As the core component of the photovoltaic energy storage system, the energy storage cabinet is like an intelligent energy steward, shouldering the key mission of balancing

Problems with Chemical Energy Storage: Challenges and

Aug 20, 2024 · Let''s face it: chemical energy storage is like that friend who''s *almost* reliable. You know, the one who shows up late but still brings pizza. While batteries and hydrogen fuel

How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Feb 21, 2025 · Manufacturing a Battery Energy Storage System (BESS) cabinet is a complex process that involves designing, engineering, and assembling a robust and reliable system to

How many steps are required to process energy storage cabinets?

Apr 15, 2024 · The process of energy storage cabinets involves 1. Evaluating Needs, 2. System Design, 3. Component Selection, 4. Installation, 5. Testing and Commissioning, 6.

What tests are performed on energy storage cabinets?

Jun 1, 2024 · Energy storage cabinets undergo a series of tests to ensure functionality, safety, and efficiency. These tests include 1. performance assessment, 2. safety inspection, 3.

Technical Difficulties of Energy Storage Cabinets

Energy storage: Navigating challenges and opportunities Energy storage is an issue at the heart of the transition towards a sustainable and decarbonised economy. One of the many

Energy Storage Cabinet 2025: The Game-Changer in Power

May 27, 2019 · That''s what using outdated power solutions feels like in 2025. Enter the energy storage cabinet – the Swiss Army knife of modern electricity management. These metallic

What are the common problems of energy storage

Various application domains are considered. Energy storage is one of the hot points of research in electrical power engineering as it is essential in power systems. It can improve power system

What is the principle of energy storage cabinet | NenPower

Jul 24, 2024 · During the charging phase, energy flows into the battery cells from an external source. This process often engages in managing discrepancies between energy production

Production and assembly of energy storage cabinets

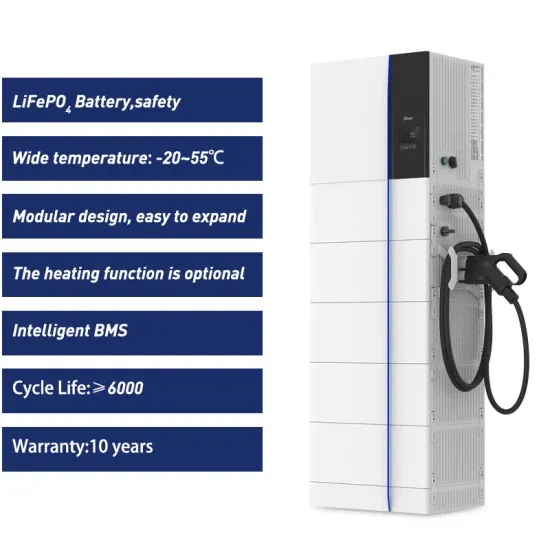

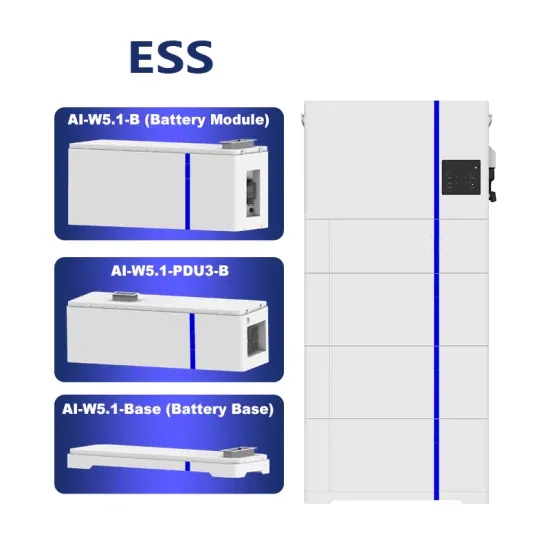

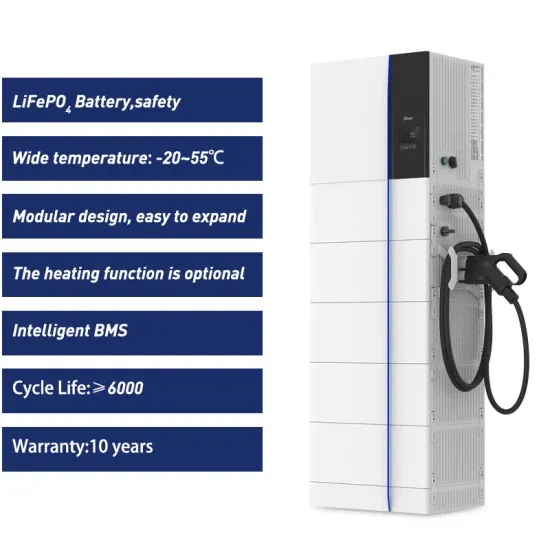

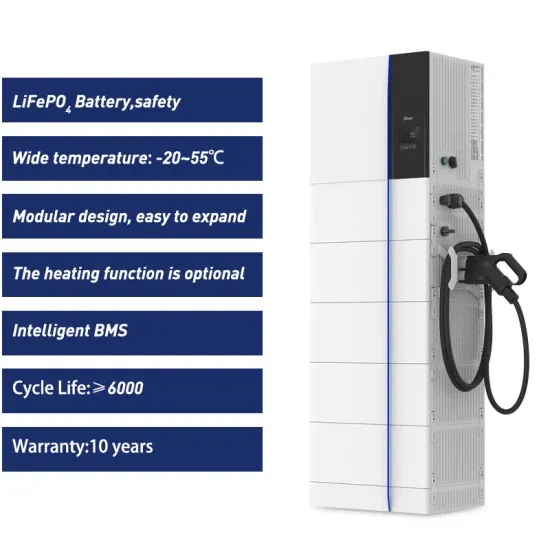

The following are several key design points: Modular design: The design of the energy storage cabinet should adopt a modular structure to facilitate expansion, maintenance and

Problems in the production process of energy storage

through the storage and release of energy storage cabinets, industrial energy storage batteries can help balance the grid load, reduce energy waste during peak hours,

Energy Storage Cabinets: Unveil the Reliable Supply Secrets

May 2, 2025 · Cost – Efficiency A reliable supply chain also contributes to cost – efficiency. When a supplier can consistently meet the demand for energy storage cabinets, it helps in avoiding

Control electrical cabinets as the foundation of smart production

Nov 24, 2023 · Industry 4.0 revolutionizes the manufacturing process, where smart systems and modern technologies are key drivers of innovation. At the center of the energy transformation,

analysis and solutions to common problems in energy storage cabinets

Analysis and Solutions to Common Management Problems in Analysis of township enterprise management issues and countermeasures under the new situation. Brand Research, 2021,

What are the common problems with energy storage

Numerous crucial factors must be taken into account for Energy Storage System (ESS) sizing that is optimal. Market pricing, renewable imbalances, regulatory requirements, wind speed

Analysis of the Difficulties in Manufacturing Energy

Energy storage systems (ESS) are continuously expanding in recent years with the increase of renewable energy penetration, as energy storage is an ideal technology for

Can the capacity of energy storage cabinets be increased

A Commission Recommendation on energy storage (C/2023/1729) was adopted in March 2023. It addresses the most important issues contributing to the broader deployment of energy

Which factories need energy storage cabinets? | NenPower

Apr 24, 2024 · 1. Energy storage cabinets are essential in a variety of manufacturing and industrial settings, but not every factory demands their presence.2. Essential locations include

What are the heat dissipation issues of energy

Jun 11, 2024 · The amplification of energy density in batteries and capacitors implies that energy storage systems are tasked with handling greater amounts

The Art and Science Behind Energy Storage Cabinet Production

Let''s pull back the curtain on energy storage cabinet production – where engineering precision meets renewable energy magic. From Tesla''s Powerwall to industrial-scale behemoths, these

Manufacturing of energy storage cabinets

Flexible,scalable design for efficient energy storage. Energy storage is critical to decarbonizing the power system and reducing greenhouse gas emissions. It''s also essential to build

Production Flow Chart of Energy Storage Battery Cabinets: A

Why Energy Storage Battery Cabinet Production Needs Precision Flow Charts With global energy storage demand projected to reach $490 billion by 2030, manufacturers can''t afford

Common Problems of Energy Storage Capping Machines: A

Mar 29, 2024 · Let''s face it – energy storage capping machines are like the unsung heroes of the renewable energy world. While everyone''s busy oohing and aahing over solar panels and wind

Energy Storage Cabinet Production Line

6 days ago · This production line is used for automatic assembly of energy storage cabinets. All single machine equipment and distributed systems interact with MES through a scheduling

Technical difficulties of energy storage cabinets

hnical Difficulties of Energy Storage Containers. Hydrogen is increasingly being recognized as a promising renewable energy carrier that can help to address the intermittency issues

Comprehensive review of energy storage systems

Jul 1, 2024 · Battery, flywheel energy storage, super capacitor, and superconducting magnetic energy storage are technically feasible for use in distribution networks. With an energy density

Challenges and Solutions in the Energy Storage

Mar 7, 2025 · In this article, we explore the key difficulties confronting the energy storage sector and the innovative solutions that are being developed to

Smart energy storage cabinet production process

Industry 4.0 revolutionizes the manufacturing process, where smart systems and modern technologies are key drivers of innovation. At the center of the energy transformation, control

Energy storage cabinet production process flow chart

storage systems play in transforming energy systems? Battery energy storage syste ritical rolein transforming energy that will be clean,eficient,and sustainable. May this handbook serve as a

6 FAQs about [Problems in the production process of energy storage cabinets]

What should be included in a technoeconomic analysis of energy storage systems?

For a comprehensive technoeconomic analysis, should include system capital investment, operational cost, maintenance cost, and degradation loss. Table 13 presents some of the research papers accomplished to overcome challenges for integrating energy storage systems. Table 13. Solutions for energy storage systems challenges.

What is the complexity of the energy storage review?

The complexity of the review is based on the analysis of 250+ Information resources. Various types of energy storage systems are included in the review. Technical solutions are associated with process challenges, such as the integration of energy storage systems. Various application domains are considered.

What are the challenges to integrating energy-storage systems?

This article discusses several challenges to integrating energy-storage systems, including battery deterioration, inefficient energy operation, ESS sizing and allocation, and financial feasibility. It is essential to choose the ESS that is most practical for each application.

Why is electricity storage system important?

The use of ESS is crucial for improving system stability, boosting penetration of renewable energy, and conserving energy. Electricity storage systems (ESSs) come in a variety of forms, such as mechanical, chemical, electrical, and electrochemical ones.

What factors must be taken into account for energy storage system sizing?

Numerous crucial factors must be taken into account for Energy Storage System (ESS) sizing that is optimal. Market pricing, renewable imbalances, regulatory requirements, wind speed distribution, aggregate load, energy balance assessment, and the internal power production model are some of these factors .

How does battery SoC affect ESS Energy Storage System performance?

In Ref. , it is represented a control strategy to manage a BESS in a microgrid for enhancing the ESS life time based on battery SOC and maximum capacity. The overall BESS life span enhanced by 57 %. 4.2. Battery SOC effects on ESS Energy storage systems' stability and performance are highly affected by the SOC.

Learn More

- Difficulties in the production process of energy storage containers

- Belarusian Industrial and Commercial Energy Storage Cabinets

- The process of the communication base station battery energy storage system is

- Ranking of portable lithium battery energy storage cabinets

- Communication high voltage energy storage cabinet assembly plan and process

- What is the process for replacing the battery energy storage system of a communication base station

- Free installation of industrial and commercial energy storage cabinets

- Supplier of industrial energy storage cabinets in Hamburg Germany

- What are the manufacturers of large energy storage cabinets in Muscat

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.