A novel high reflective glass-ceramic ink with Bi

Jul 1, 2023 · Photovoltaic glass ink is a kind of ink used for the photovoltaic glass backplane to enhance the photoelectric conversion efficiency of solar cells. In this work, a novel kind of

Customize Your Photovoltaic Glass with Onyx Solar: Tailored

Oct 17, 2024 · SIZE, SHAPE & THICKNESS Our photovoltaic glass can be fully personalized, being adapted to the specific requirements of each project. Onyx Solar''s panes can be as

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating solar cells, and has related

Optics for concentrating photovoltaics: Trends, limits and

Jul 1, 2016 · The ability to harvest this solar energy efficiently and cost effectively however is challenging. For this reason, there is a growing interest in concentrating photovoltaic (CPV)

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

Onyx Solar: the Most Awarded Photovoltaic Glass Company

At Onyx Solar we provide tailor-made photovoltaic glass in terms of size, shape, transparency, and color for any cladding design. Our photovoltaic ventilated façades not only provide a new

An overall introduction to photovoltaic glass –

Jan 24, 2024 · Photovoltaic glass refers to the glass used on solar photovoltaic modules, which has the important value of protecting cells and transmitting

Crystalline PV Glass VS. Amorphous Silicon PV

Oct 28, 2022 · At present, BIPV combines photovoltaics with buildings and makes full use of the surface space of buildings to generate electricity, which has

Solar glass/Photovoltaic glass classification

Aug 27, 2019 · Photovoltaic glass mainly has the following characteristics: (1) high absorption rate of sunlight and low reflectivity; (2) high mechanical strength for

Onyx Solar: the Most Awarded Photovoltaic Glass Company

At Onyx Solar we provide tailor-made photovoltaic glass in terms of size, shape, transparency, and color for any canopy design. Photovoltaic canopies provide clean and free energy

Designs for photovoltaic glass surface texturing

Dec 27, 2024 · Planar glass cover creates optical reflection loss and glare, which is harmful to energy efficiency and effective operation of PV modules,

Photovoltaic Applications | Photovoltaic Research | NREL

Apr 3, 2025 · Photovoltaic Applications At NREL, we see potential for photovoltaics (PV) everywhere. As we pursue advanced materials and next-generation technologies, we are

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · Weathering of float glass can be categorized into two stages: "Stage I": Ion-exchange (leaching) of mobile alkali and alkaline-earth cations with H+/H3O+, formation of

6 FAQs about [The shape of photovoltaic glass]

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

What is the difference between Photovoltaic Glass and traditional solar PV?

The main difference between photovoltaic glass technologies and traditional solar photovoltaics (PV) is that the newer panels are built into the structure rather than being added on top, which provides an incentive for users concerned about balancing aesthetics and functionality.

What encapsulated glass is used in solar photovoltaic modules?

The encapsulated glass used in solar photovoltaic modules (or custom solar panels), the current mainstream products are low-iron tempered embossed glass, the solar cell module has high requirements for the transmittance of tempered glass, which must be greater than 91.6%, and has a higher reflection for infrared light greater than 1200 nm. rate.

Why is Photovoltaic Glass important?

Photovoltaic glass is one of the best materials to protect crystalline silicon and has high self-transmission rate for a long time. Therefore, the optical properties of photovoltaic glass are an important factor outside the crystalline silicon technology.

How is Photovoltaic Glass made?

It is made by using a special embossing roller to press a special pyramid pattern on the surface of the ultra-white glass, as shown in Figure 1. At present, there are mainly the following two production processes for photovoltaic glass. (1) The production process of Gridfa glass was invented in 1961 by the Belgian Gravibel Manufacturing Company.

What is the classification of Photovoltaic Glass?

The classification of photovoltaic glass mainly includes ultra white photovoltaic embossed glass, ultra white processed Float glass, TCO glass and backplane glass. The main characteristics are analyzed as follows: (1) Ultra White Photovoltaic Embossed Glass

Learn More

- Oslo double glass photovoltaic module price

- Photovoltaic glass opens up demand space

- Is ultra-white glass photovoltaic glass

- Environmental protection requirements for photovoltaic glass

- The difference between ito conductive glass and photovoltaic glass

- Photovoltaic glass heating

- Maputo Photovoltaic Conductive Glass

- Is there a photovoltaic glass factory in Warsaw

- Filling holes in photovoltaic panel glass

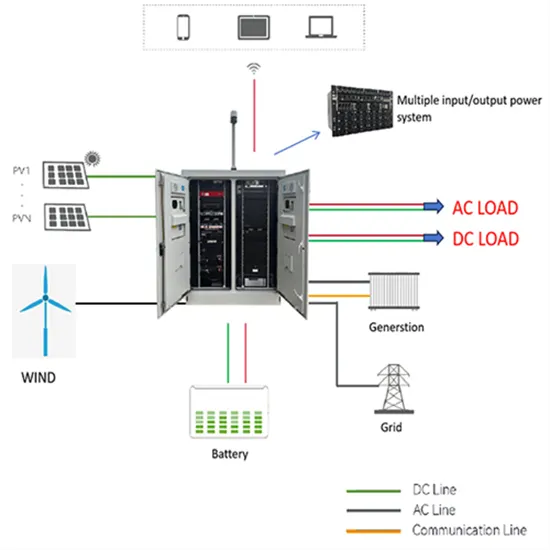

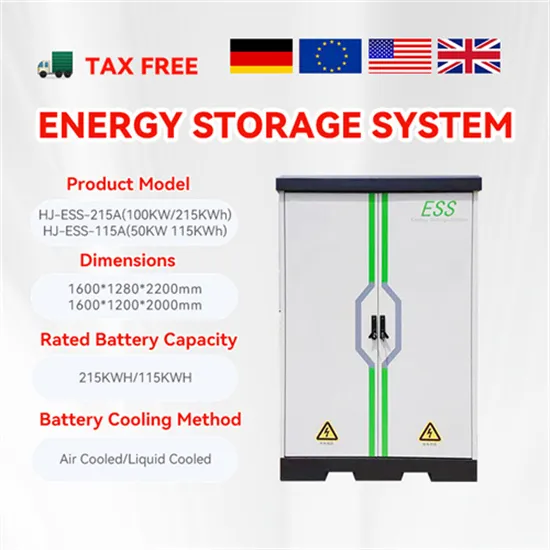

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.