Plant Safety Inspection & Industrial Assets

Plant Safety Equipment Inspection covers those topics for industrial equipment & installations as well as for airfield and fuel systems to fill vehicles or any storage of oils or substances harmful

The design and implementation of mobile communication base station

Dec 31, 2012 · The Mobile Communication Base Station Inspection is one type of basic work to ensure safe operation of the base station equipment. By using the mobile applicati

Design and realization of 5G mobile base station s

Feb 28, 2024 · The construction of the information management concept of inspection report is realized, and a set of solutions that can be implemented on the ground is provided to improve

How to Conduct Effective Construction Site Inspections

Sep 20, 2024 · Effective construction site inspections encompass several key elements that contribute to their success: Planning and Preparation: Thorough planning is essential. Identify

Design and implementation of a computerized safety inspection

Nov 1, 2021 · The implementation and evaluation of Smart Inspecs were performed at two construction sites, totaling 55 inspections and involving seven direct users. The application of

Research on Base Station Site Planning Based on Cluster

Jan 9, 2024 · The site selection is generally based on the analysis of the coverage of the live network antenna, and a certain number of points are selected to solve the problem of the weak

Parallel Inspection Route Optimization With Priorities for 5G Base

Jan 16, 2025 · 5G base station networks generate numerous alarms daily. With the increasing demand for digital services, it is vital to inspect and rectify anomalies to uphold user

How to Conduct a Successful Construction Site Inspection

Mar 2, 2025 · Construction site inspections are critical to ensuring the safety, quality, and compliance of building projects. They serve as an essential checkpoint for identifying issues,

Comparing Inspection Strategies For Hydrogen

Jun 21, 2024 · The results show how a risk-based approach can provide a comprehensive and adaptive inspection framework for hydrogen refueling stations. Keywords: hydrogen refueling

Base station inspection method and system

The embodiment of the invention provides a base station inspection method and system, and the method comprises the steps: terminal equipment displays a plurality of inspection items when

Site Inspection Drone: A Solution for Inspecting and

Sep 30, 2023 · The database information is sent wirelessly to the base station, responsible for scheduling inspections, and defining the site location and building codes that should be

What Are The Requirements For Base Station Tower Maintenance

Jun 1, 2020 · The main contents of the site inspection and maintenance of the base station tower include: basic inspection, verticality inspection, bolt filling and tightening, component

Regulations of Shanghai Municipality on the Administration

Dec 2, 2024 · 1. to request the unit being inspected to provide materials on the quality and safety of a construction engineering; 2. to enter the construction site of the unit being inspected to

A Guide to Conducting Effective Safety Inspections

Feb 11, 2025 · Conducting the Inspection Once preparation is complete, the focus shifts to the actual inspection process. Initial Walkthrough Begin with a casual

Waste Transfer Stations: A Manual for Decision-Making

Jun 25, 2021 · For publicly developed transfer stations, a good first step by public officials in the site selection process is establishing a siting com-mittee. The committee''s main responsibility

Base Station Installation & Maintenance Test Solutions

Using the Site Master, which acts as a Vector Network Analyzer, enables the evaluation of cable and connector losses and reflections from the antenna, which need to be considered at the

6 FAQs about [Base station site inspection process]

What is a construction site inspection?

Construction site inspections are a vital component of project management, ensuring safety, quality, and adherence to regulations. By following the guidelines and best practices outlined in this comprehensive guide, you can conduct effective inspections that contribute to the success of your construction projects.

How can a construction site inspection be improved?

Embrace Technology: Utilize advanced inspection techniques, such as drones, 3D laser scanning, and BIM, to enhance the effectiveness and efficiency of the inspection process. Construction site inspections are a vital component of project management, ensuring safety, quality, and adherence to regulations.

What are the best practices for a construction site inspection?

To ensure the effectiveness of your construction site inspections, adhere to the following best practices: Be Thorough and Systematic: Follow a structured inspection process, covering all relevant areas and activities on site. Use checklists to ensure thoroughness and consistency. Prioritize Safety: Always prioritize safety.

How do inspectors prepare for a site inspection?

Pre-Inspection: Before the inspection, the inspectors will prepare themselves by collecting and reviewing necessary documentation and plans. They might request access to the layout of the site, detailed scope of work, safety records, and previous compliance reports.

What should be included in a construction site inspection?

To effectively manage a construction site inspection, a comprehensive checklist is essential. This checklist should include: Structural Integrity: Examine the strength and durability of foundations, framing, and other structural elements. Electrical Systems: Ensure that all wiring, circuit breakers, and safety switches meet safety standards.

What is a construction site?

Construction sites are dynamic and complex environments, where numerous activities occur simultaneously, often involving heavy machinery, hazardous materials, and a large workforce. Amidst this complexity, ensuring safety, quality, and adherence to regulations is paramount.

Learn More

- Base station site density derivation

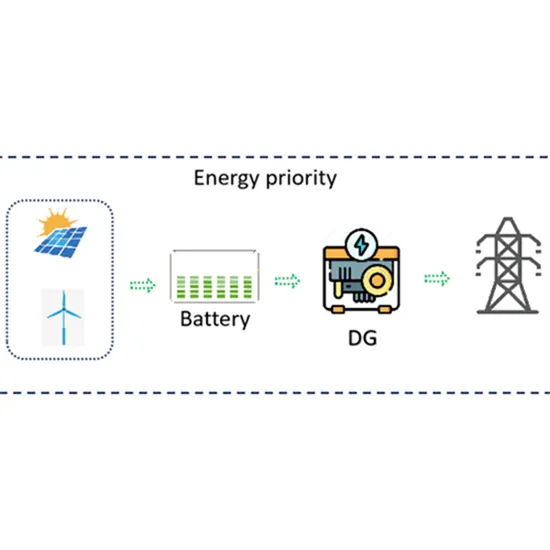

- Communication base station hybrid energy site power supply

- Nairobi lithium battery site cabinet base station

- Athens Communication Base Station Wind Power Outdoor Site

- Photovoltaic process of communication base station energy management system

- Solar Base Station Installation Process

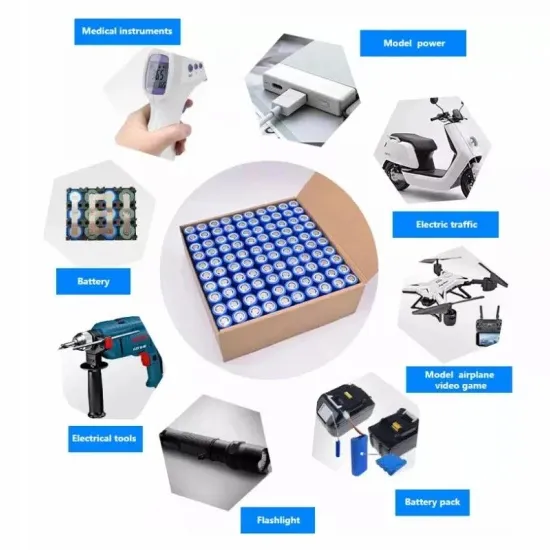

- The process of the communication base station battery energy storage system is

- Site communication of wireless outdoor base station AP energy storage cabinet

- Battery installation process for communication base station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.